Last active

July 3, 2025 14:39

-

-

Save guohaiping/a28574744a887269a5a2ba4bed56c65d to your computer and use it in GitHub Desktop.

CBuilder_Tutorial

This file contains hidden or bidirectional Unicode text that may be interpreted or compiled differently than what appears below. To review, open the file in an editor that reveals hidden Unicode characters.

Learn more about bidirectional Unicode characters

| # CBuilder FX Tutorial | |

| RSCAD®Fx | |

| # Table of Contents | |

| 1 MULTIPLE INPUT ADDER 1 | |

| 1.1 Introduction 1 1.2 Create a New Component. 1 1.3 Create the Required Parameters 2 1.5 Draw the Graphics. 5 1.6 Add the IO Points. 11 1.7 Adding the Model Code. 14 1.8 Sample $^{\prime}C^{\prime}$ Code for the Multiple Input Adder. 15 2 INTEGRATOR. 1 2.1 Introduction. 1 2.2 draw Graphics and Add Parameters. 2 2.3 Adding the Model Code. 2 2.4 Sample $^{\prime}C^{\prime}$ Code for an Integrator. 3 2.5 Add a Reset Input to the Integrator. 4 3 VARIABLE CAPACITOR. 1 3.1 Introduction. 1 3.2 Capacitor. 2 3.3 Draw Graphics and Add Parameters. 3 3.4 Adding the Model Code. 4 3.5 Adding an Optionally Monitored Variable. 6 4 MULTI- MASS SYSTEM. 1 4.1 Introduction. 1 4.2 Single Mass Rotating About And Axis. 2 4.2.1 Equations Of Motion Representing A Single Mass Rotating About An Axis. 2 4.3 Damping. 4 4.4 Two Rotating Masses Coupled By A Shaft. 6 4.4.1 Equations Of Motion For 2 Rotating Masses Coupled By A Shaft. 6 4.5 Multi- Mass Model Using Matrix Formulation. 9 4.6 Multi- Mass Model Algorithm. 11 4.7 Model Development Using C- Builder. 11 4.7.1 Conceptual Layout Of The New Component. 11 | |

| 4.7.2 Component Icon Creation In C- Builder (Graphics & Nodes) 12 4.7.3 Define User Supplied Data Menus (Parameters) 12 4.7.4 Write Data Preparation Portion Of The 'C' Program 12 4.7.5 Write 'C' Code To Implement The Algorithm 12 4.7.6 Test Newly Developed Model 12 4.7.7 Conceptual Layout Of The New Component 12 4.7.8 Component Icon Creation In C- Builder 15 4.7.9 Add Parameter Entry Menus 20 4.7.10 Write Data Preparation Portion Of The 'C' Program 22 4.7.11 Write 'C' Code To Implement The Algorithm 25 4.7.12 Test Newly Developed Model 30 | |

| 4.8 References 31 | |

| 5 MULTI- THREAD COMPONENT 1 | |

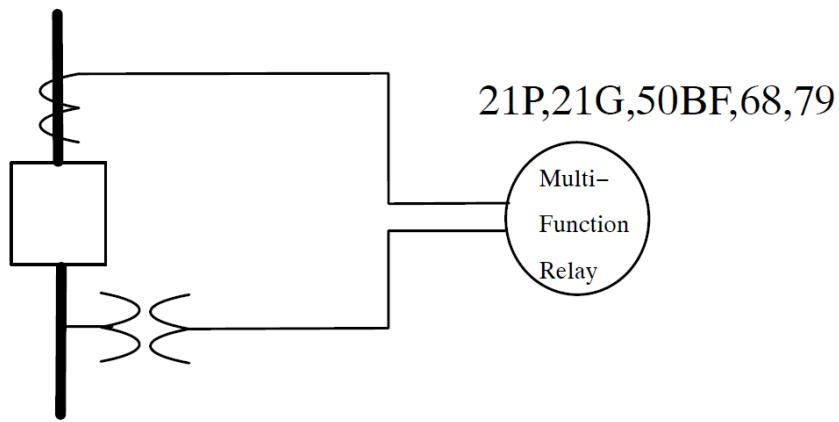

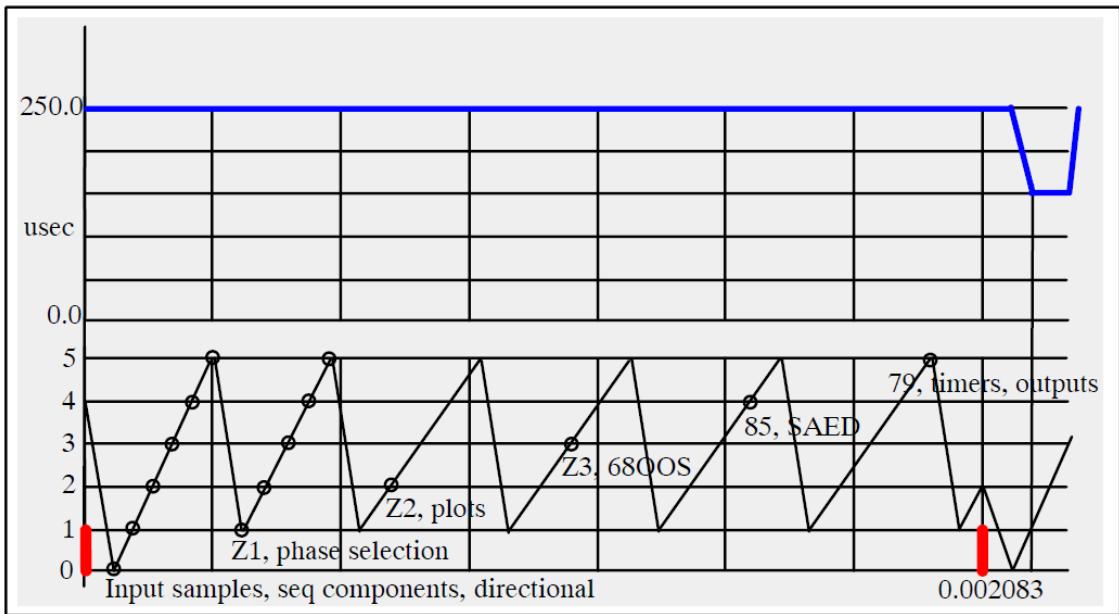

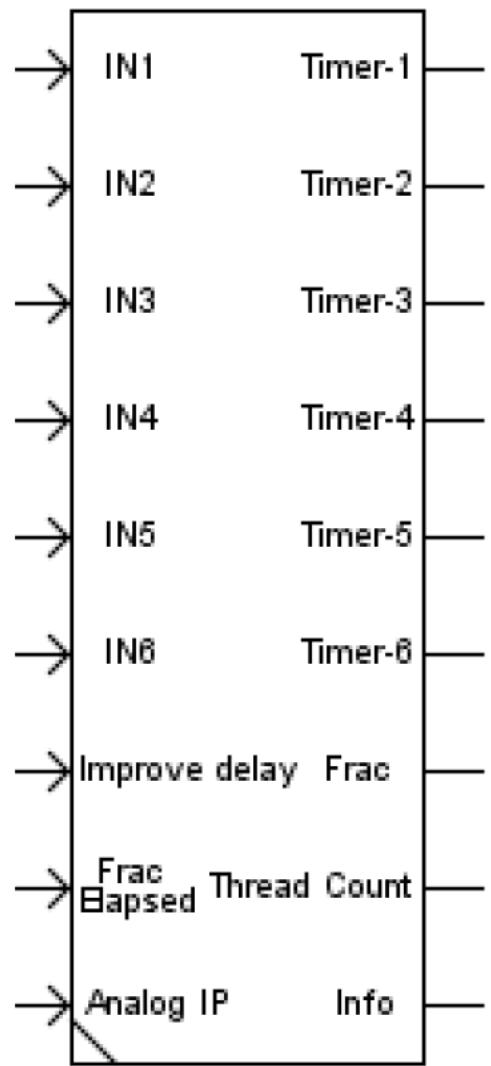

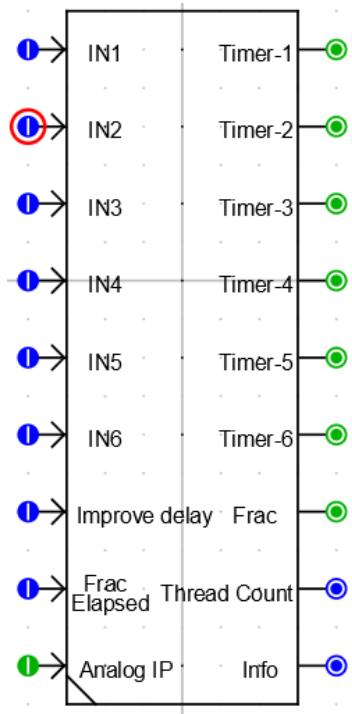

| 5.1 Introduction 1 5.2 Multi- Function Relays 2 5.3 Multi- Thread Component 2 5.4 Model Development using CBuilder 3 5.5 Multi- Thread Model Algorithm 12 5.6 Multi- Thread Static Section 13 5.7 Multi- Thread Ram section 14 5.8 Multi- Thread Code Section 17 | |

| 6 PMU SHELL COMPONENT 1 | |

| 6.1 Introduction 1 6.2 Phasor Measurement Unit 1 6.3 Model Development using CBuilder 2 6.4 PMU Shell Component 3 6.5 Load PMU Shell into CBuilder 3 6.6 PMU Shell Algorithm 4 6.7 C Code Sections 6 6.8 References 11 | |

| 7 GENERATOR CONTROL BLOCK 1 | |

| 7.1 Introduction 1 7.2 Draw Graphics and Add Parameters 1 | |

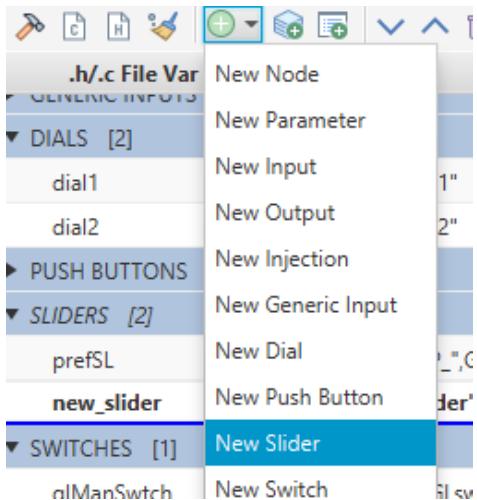

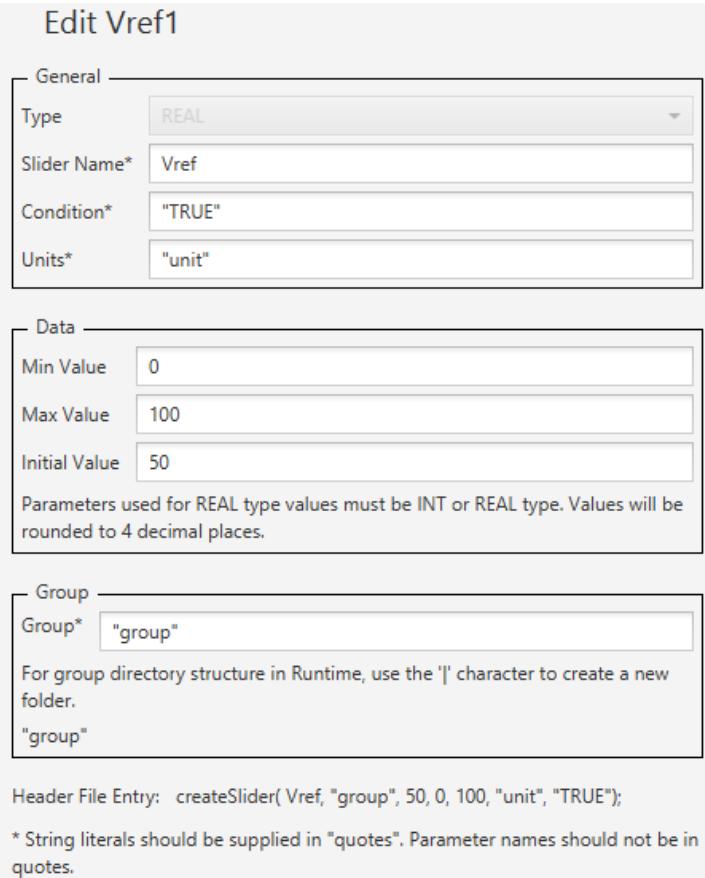

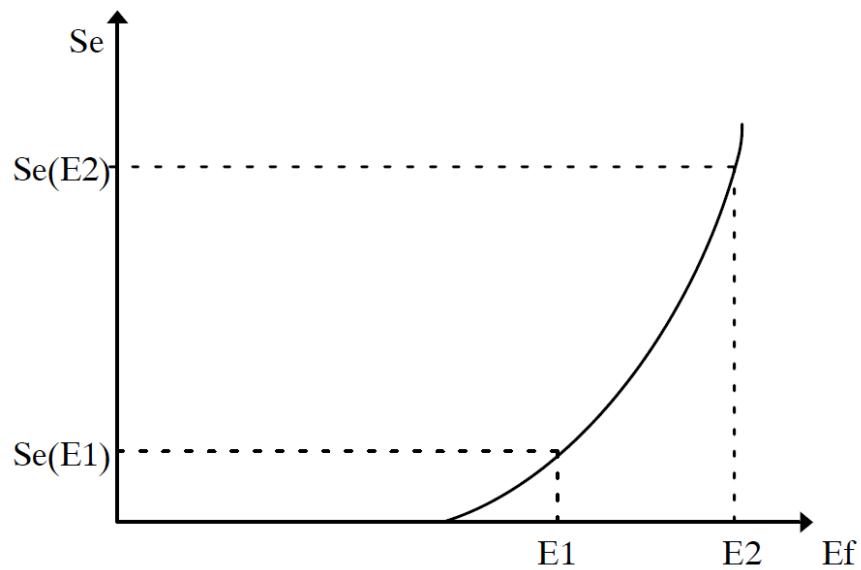

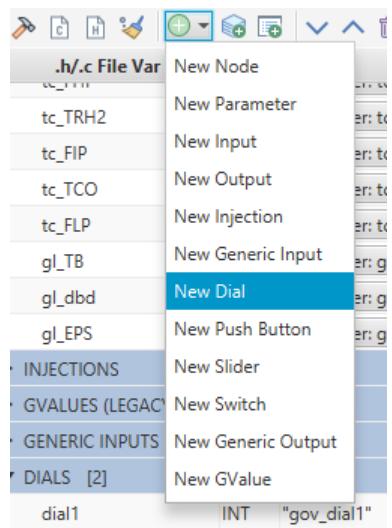

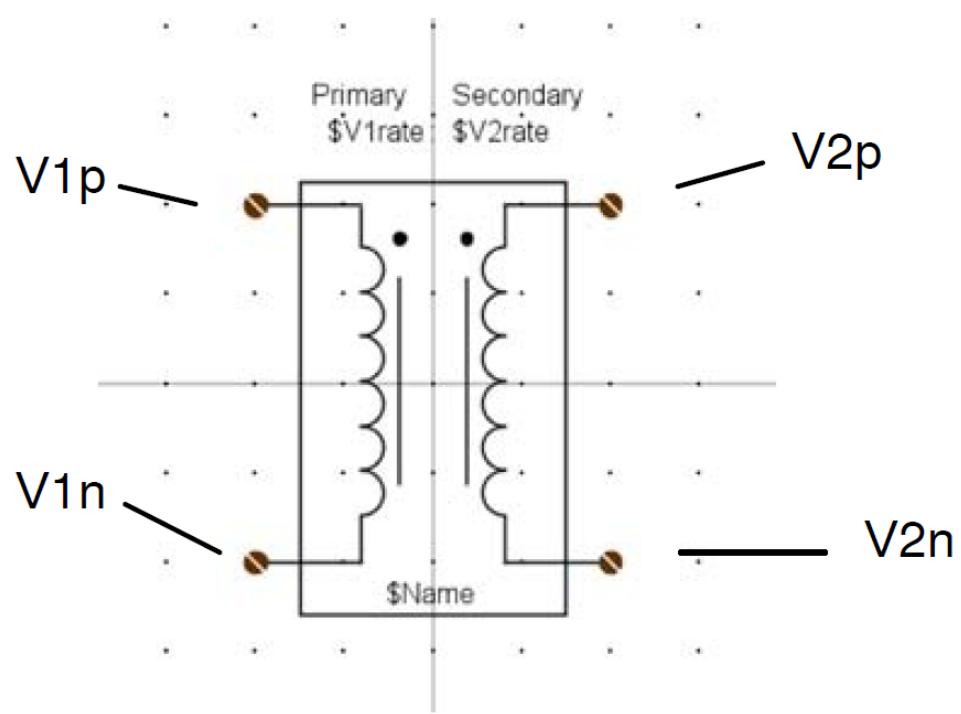

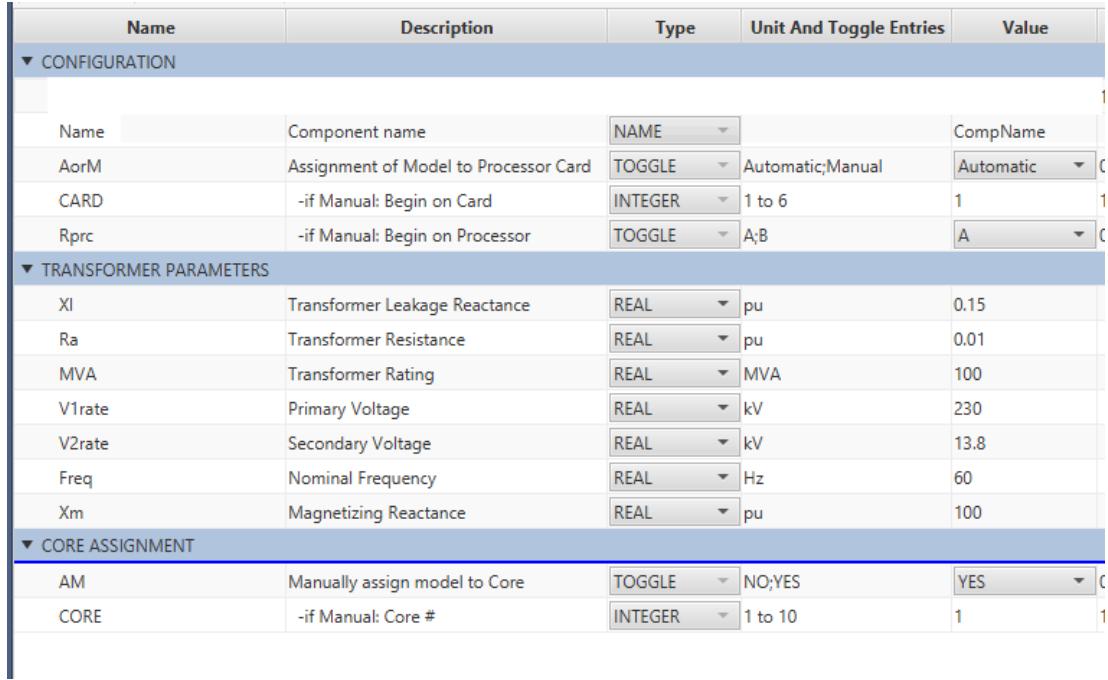

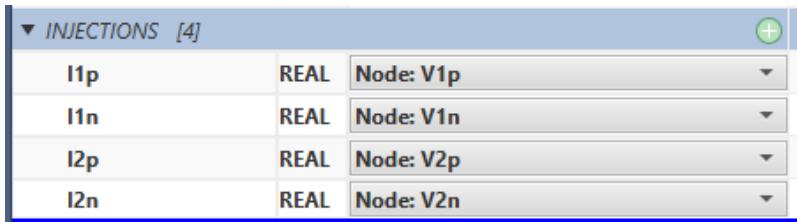

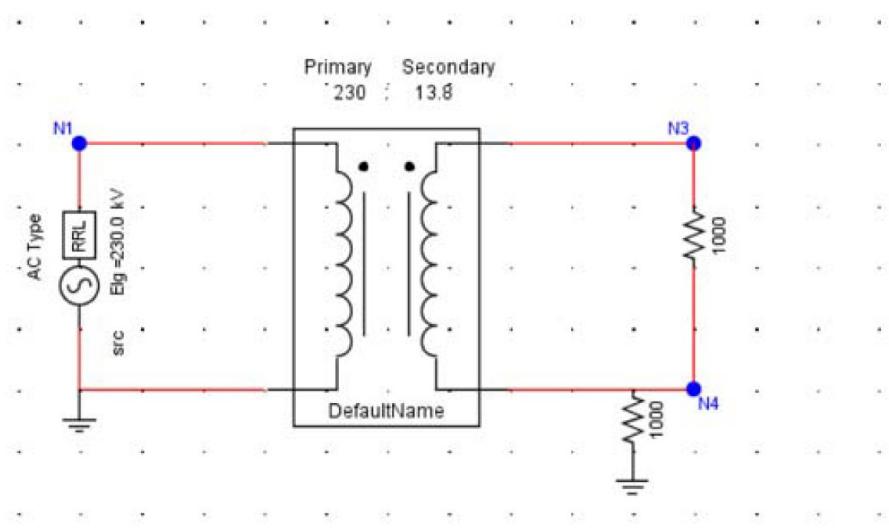

| 7.3 Adding the Model Code 27.4 Sample 'C' Code for the DC1 Type Exciter 37.5 Data Preparation and Initialization 117.6 Add an internal Slider 137.7 Add Code for realpole Function 157.8 Add Code leadlag Function 157.9 Add Code for washOut Function 157.10 Add Code for Saturation Function 167.11 Adding the Code 167.12 Add a Dial to Select InterNal Variables for Monitoring 207.13 Add a Generic Output 217.14 Add Monitoring Code 218 SIMPLE TRANSFORMER 18.1 Introduction 18.2 Theory 18.2.1 Modelling a Transformer 18.2.2 RTDS Solution Algorithm 48.2.3 Integrating the Transformer Model into the RTDS Solution Algorithm 58.2.4 Generalizing the Transformer Equations 98.3 Draw Graphics and Add Parameters 118.4 Adding the Model Code 128.5 Basic Algorithm 138.6 References 199 MULTIPLIER WITH COMPLEX NUMBERS AS INPUTS 19.1 Introduction 19.2 Create the Required Parameters 19.3 Add the IO Points 29.4 Adding the Model Code 39.5 Sample 'C' Code for the Multiple Input Multiplier with Complex Number Inputs 4 | |

| # 1 MULTIPLE INPUT ADDER | |

| # 1.1 INTRODUCTION | |

| Simple use of the Component Builder (CBuilder) module in RSCAD FX is going to be detailed in this chapter. CBuilder module lets users' create their own components for RSCAD. The CBuilder FX includes a conversion utility to convert CBuilder components created in older versions of RSCAD into RSCAD FX. | |

| In this tutorial chapter, the user will build an adder component that can add or subtract two or three inputs. This adder will be able to accept real type inputs. | |

| # 1.2 CREATE A NEW COMPONENT | |

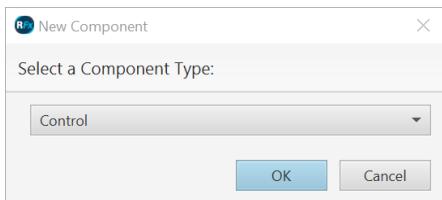

| Start RSCAD, Open "Component Builder" from the Launch menu. Select "New Component" at the welcome dialog. Select "Control" for the Component Type | |

|  | |

| Figure 1.1: Set Initial Options Menu | |

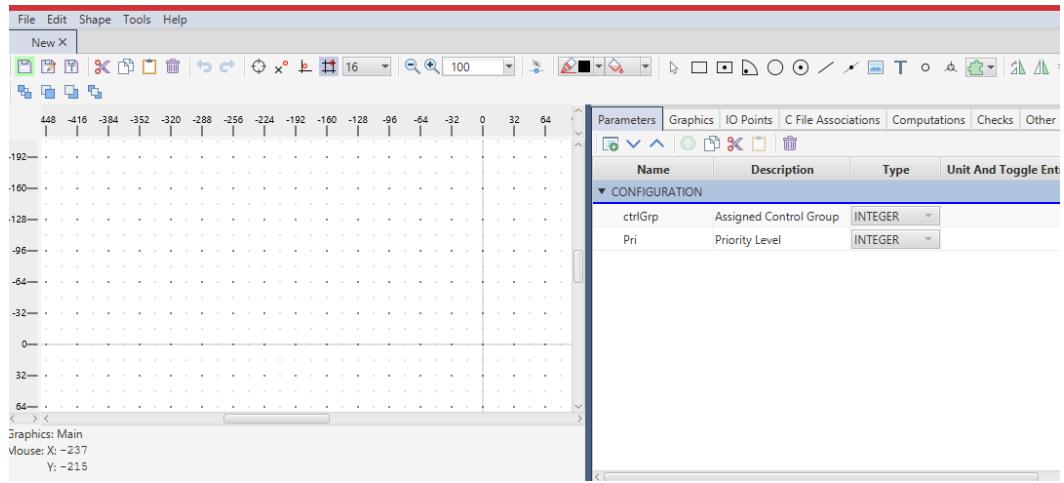

| The CBuilder module will appear as shown in Figure 1.2. | |

|  | |

| Figure 1.2: CBuilder FX | |

| - Save the component as "tutorialc". It will have a .def file extension. | |

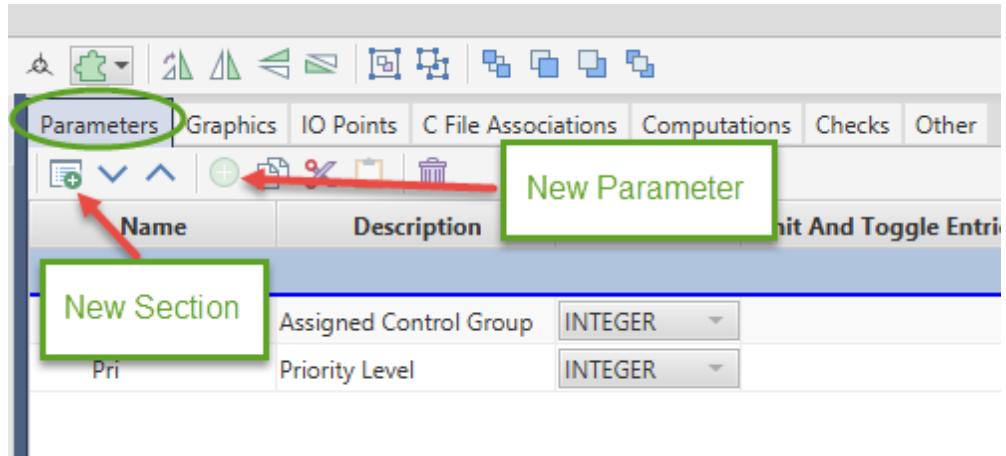

| # 1.3 CREATE THE REQUIRED PARAMETERS | |

| The required parameters are going to be added into a new section. Each section will appear as a separate tab in Draft when you edit the parameters of the component. The "New Section" and "New parameter" buttons are identified in the toolbar in Figure 1.3. | |

| - Select the Parameters tab. | |

|  | |

| Figure 1.3: Parameters Tab | |

| - Add a new section titled "addercontrol" | |

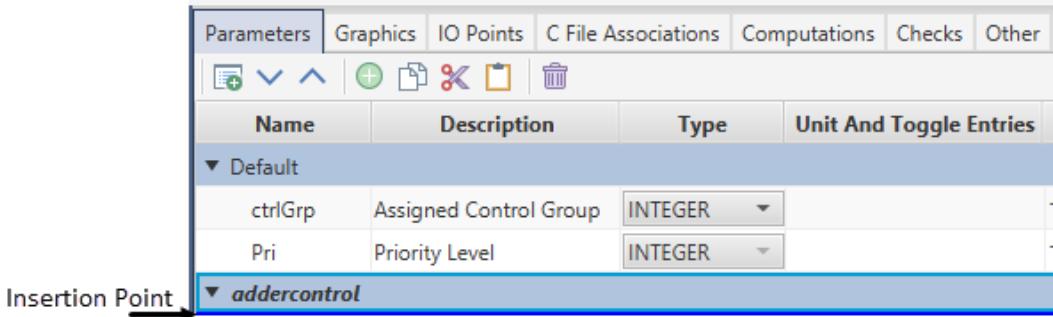

| - New parameters will be added at the insertion point, which is a blue line in the table. By clicking on a section header, the insertion point will be placed at the end of that section. Click on a existing parameter and the insertion point will be placed immediately after that parameter. Before adding a new parameter ensure that the | |

| # insertion point is in the section "addercontrol". | |

|  | |

| Figure 1.4:Insertion Point | |

| A number of fields must be entered to define each new parameters. Add the following parameters to the newly created section. | |

| # Parameter #1 | |

| <table><tr><td>Name</td><td>numInputs</td></tr><tr><td>Description</td><td>Number of Inputs</td></tr><tr><td>Type</td><td>INTEGER</td></tr><tr><td>Unit And Toggle Entries</td><td><leave blank></td></tr><tr><td>Value</td><td>2</td></tr><tr><td>Min</td><td>2</td></tr><tr><td>Max</td><td>3</td></tr></table> | |

| </leave> | |

| # Parameter #2 | |

| <table><tr><td>Name</td><td>sign1</td></tr><tr><td>Description</td><td>Sign of Input 1</td></tr><tr><td>Type</td><td>TOGGLE</td></tr><tr><td>Unit And Toggle Entries</td><td>Add;Subtract</td></tr><tr><td>Value</td><td>Add</td></tr><tr><td>Min</td><td>0</td></tr><tr><td>Max</td><td>1</td></tr></table> | |

| The toggle entries must be entered separated by semicolon ";" | |

| The parameter sign1 will be assigned a value of 0 if the "Add" toggle entry is selected, it will be assigned a value of 1 if "Subtract" is selected. | |

| Inputs sign2 and sign3 must also be added as parameters. They can be added manually or the existing sign1 parameter can be copied, pasted and modified. Note the sign3 is conditionally enabled. | |

| # Parameter #3 | |

| Parameter #4 | |

| <table><tr><td>Name</td><td>sign2</td></tr><tr><td>Description</td><td>Sign of Input 2</td></tr><tr><td>Type</td><td>TOGGLE</td></tr><tr><td>Unit And Toggle Entries</td><td>Add;Subtract</td></tr><tr><td>Value</td><td>Add</td></tr><tr><td>Min</td><td>0</td></tr><tr><td>Max</td><td>1</td></tr></table> | |

| <table><tr><td>Name</td><td>sign3</td></tr><tr><td>Description</td><td>Sign of Input 3</td></tr><tr><td>Type</td><td>TOGGLE</td></tr><tr><td>Unit And Toggle Entries</td><td>Add;Subtract</td></tr><tr><td>Value</td><td>Add</td></tr><tr><td>Min</td><td>0</td></tr><tr><td>Max</td><td>1</td></tr><tr><td>Enabled Condition</td><td>numInputs&gt;2</td></tr></table> | |

| # 1.4 DRAW THE GRAPHICS | |

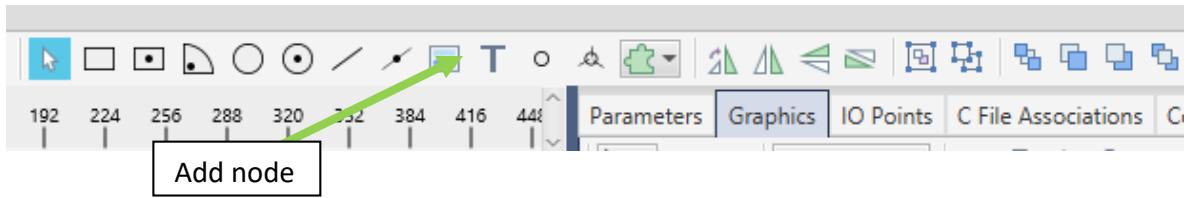

| The main toolbar shown in Figure 1.5 contains tools for drawing the component's graphics. | |

|  | |

| Figure 1.5: Tools For Drawing Component Graphics | |

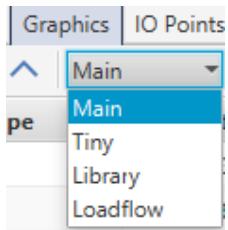

| There are four sections of graphics for each component. The user can switch between these graphics section using a dropdown in the Graphics tab which is shown in Figure 1.6. 1. Main | |

| 1. Main | |

| 2. Tiny3. Library4. Loadflow | |

| Note: All four sections should be present for all components. The later chapters will not further discuss the tiny and library graphics, but it is the users' responsibility to make sure those sections are present and to follow the guidelines presented in this chapter. | |

|  | |

| Figure 1.6: Graphics Dropdown Menu | |

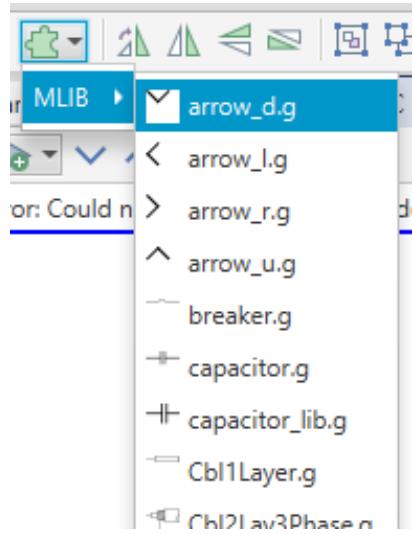

| In the toolbar, the "Add macro" dropdown menu has a collection of basic shapes that can make the drawing process efficient. | |

|  | |

| Figure 1.7: Available Macros | |

| # 1.4.1 Main Graphics | |

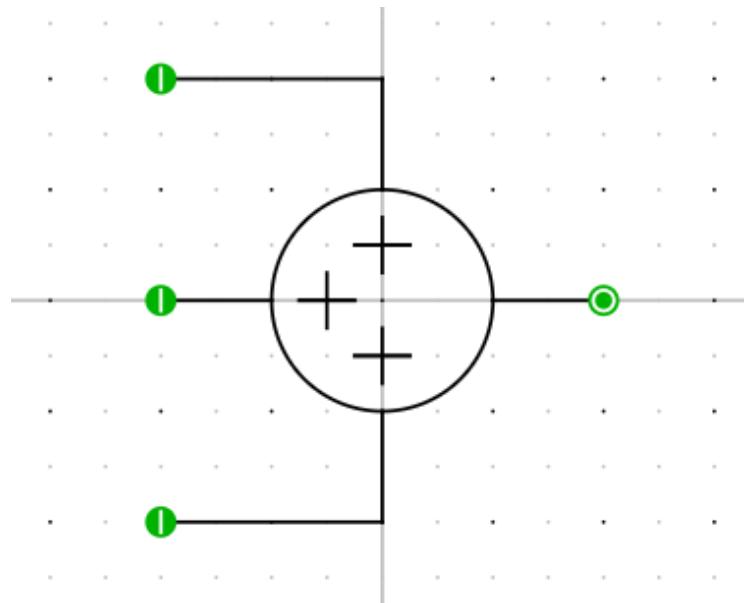

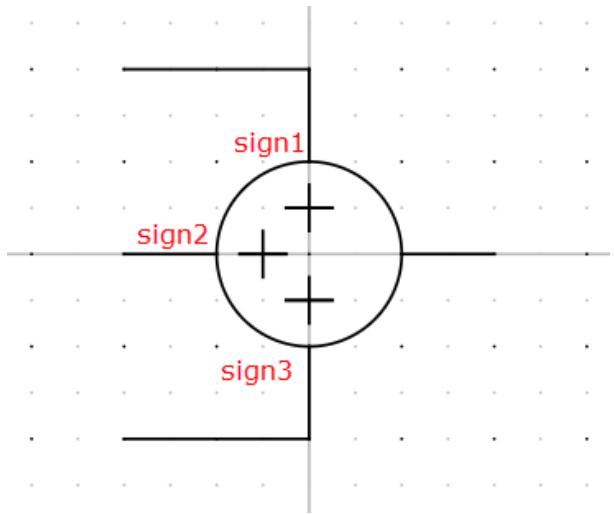

| The goal is to draw a component icon that looks similar to Figure 1.8. | |

|  | |

| Figure 1.8: Finished Component Icon | |

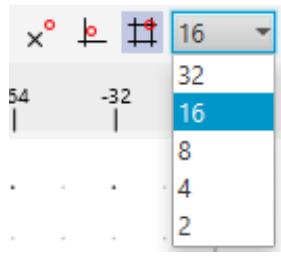

| Several snap- to options exist to make drawing component graphics easier. There are a number of helpful toolbar buttons as seen in Figure 1.9. In the figure the option "Snap to Grid" is selected. This will allow the graphical objects to snap to the points on the grid. A dropdown can be used to set the grid point spacing as small as 2 pixels, or as large as 32 pixels. The user can also choose to not snap to grid. | |

|  | |

| Figure 1.9: Grid Options | |

| - Start by drawing the unconditional graphics. The graphics can be drawn by using the drawing tools at the top toolbar of the main window. Ensure that the graphics are drawn near the center of the canvas (indicated by the intersecting lines). | |

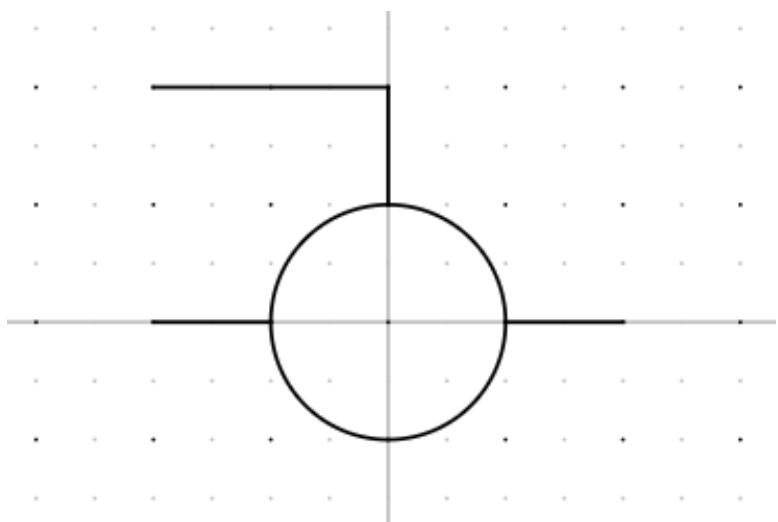

|  | |

| Figure 1.10: Drawing the Unconditional Graphics | |

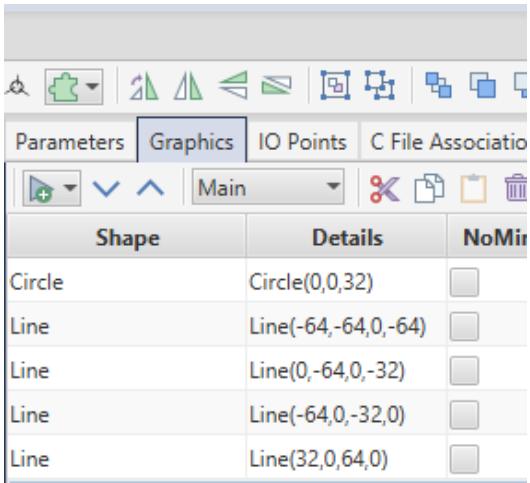

| - Select the "Graphics" tab. With the unconditional graphics drawn, the graphics section should appear similar to Figure 1.11. | |

|  | |

| Figure 1.11: Unconditional Graphics | |

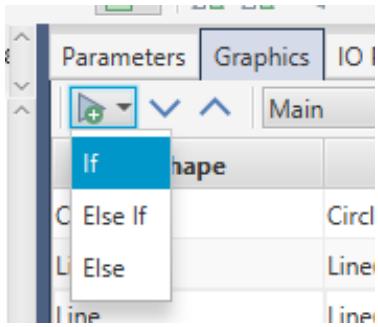

| Please refer to Figure 1.12 and Figure 1.13 for the steps below. | |

| - Add a new "If" graphics condition. This condition will be used to change the look of the icon depending on the number of inputs. | |

|  | |

| Figure 1.12: Selecting "If" from Add Condition Drop Down Menu | |

| Enter the condition sign1 $= = 0$ in the box provided. | |

| Enter the condition sign1 $= = 0$ in the box provided.- Ensure the insertion point is located within the new 'sign1 $= = 0$ ' (Add) condition. This can be done by clicking on the condition. Any graphics added will now be placed within the 'If' condition.- Draw a '+' sign with lines at the 12 o'clock position of the inside of the circle using the line tool to indicate the sign of input1. - Ensure the insertion point is inside the 'sign1 $= = 0$ ' condition. Add a new 'Else' condition. The insertion point should now be inside the Else condition (Subtract).- Draw a '+' sign over the '+' sign. The graphics for the minus sign should now appear under the Else condition. Note that the shapes inside each If/Else can be shown or hidden by clicking on the triangle beside the If/Else.- Move the insertion point outside of the conditions. This can be done by clicking on a graphical object in the tree that is not inside a condition. Repeat the above steps to create conditional graphics for 'sign2 $= = 0$ ', except put the graphics at the 9 o'clock position of the circle.- Move the insertion point outside of the conditions and add a new 'If condition'.- Enter condition 'numInputs>2'.- Ensure the insertion point is inside the 'numInputs>2' condition and draw the third input lines.- Ensure the insertion point is still inside 'numInputs>2' and add the condition 'sign3 $= = 0$ '.- Ensure the insertion point is now inside the 'sign3 $= = 0$ ' condition and add the conditional '+' and '- graphics described in previous steps at the 6 o'clock position of the circle. | |

| The icon should now appear similar to Figure 1.13. | |

|  | |

| Figure 1.13: Component Icon | |

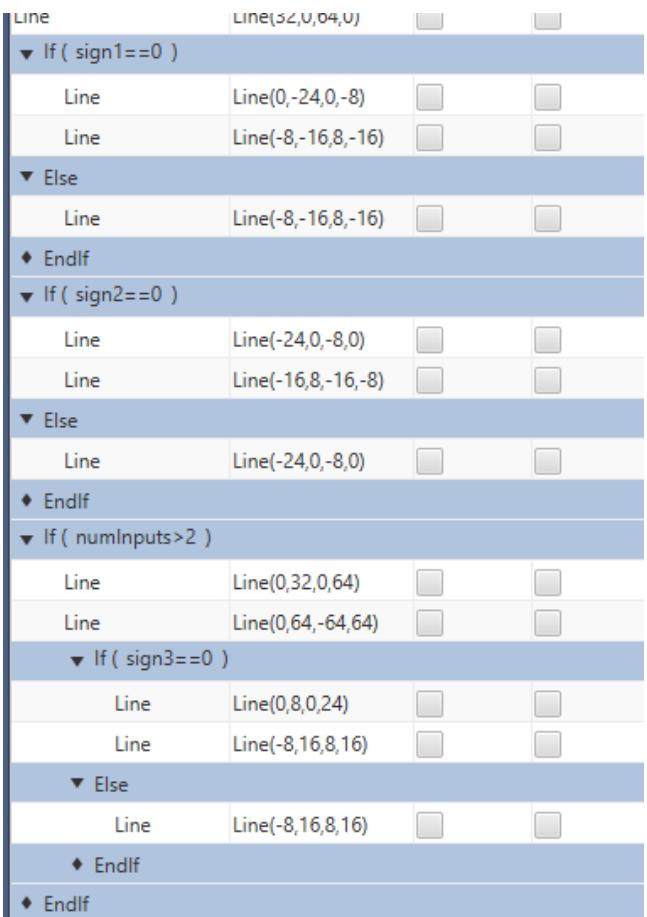

| The conditional graphics section in the graphics tab would appear as: | |

|  | |

| Figure 1.14: Conditional Section of the Graphics | |

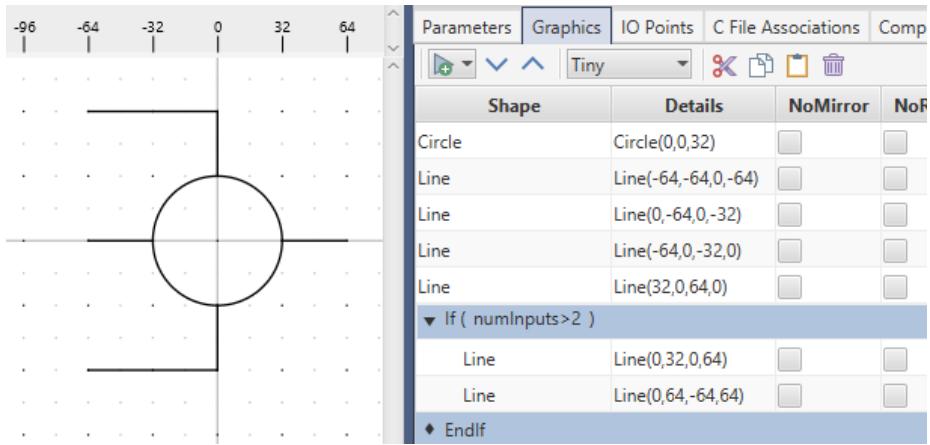

| # 1.4.2 Tiny Graphics | |

| 1.4.2 Tiny GraphicsThe tiny graphics section is used in RSCAD when the zoom level of a draft circuit is reduced beyond a chosen threshold. These graphics are meant to be a simplified representation of the component with the aim of reducing the computational burden of rendering graphics when a large network is being viewed. Minimal conditional graphics should be used. Use of text is discouraged and black should be the only graphic colour used. An example is shown in Figure 1.15. | |

|  | |

| Figure 1.15: Tiny Graphics Example | |

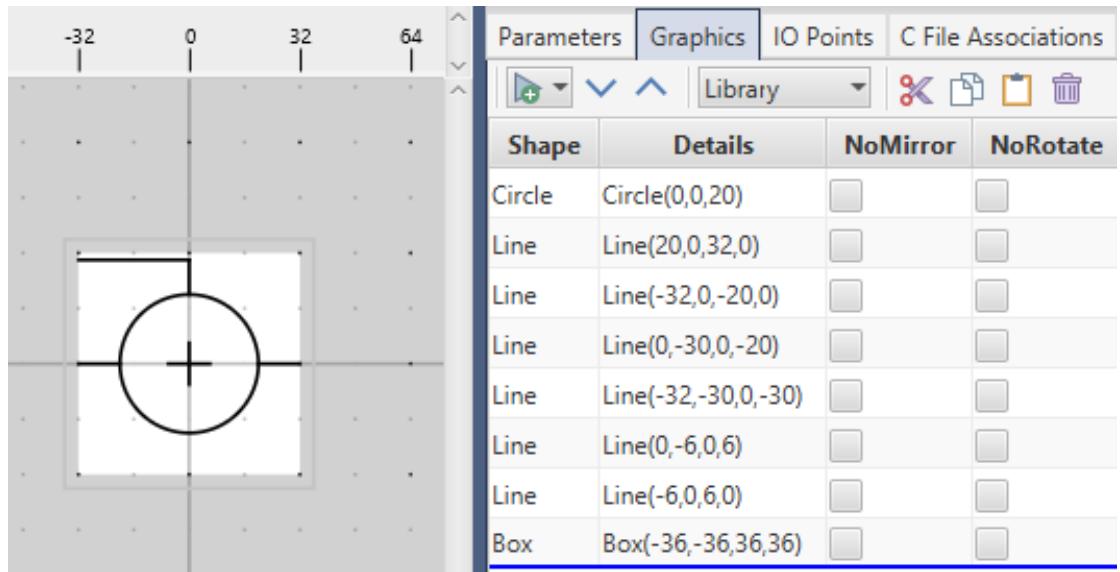

| # 1.4.3 Library Graphics | |

| 1.4.3 Library GraphicsThe library graphics are the graphics displayed in the library. This is another simpler representation of the component. Library graphics needs to be drawn in the space provided. Use of conditional graphics is discouraged. An example is shown in Figure 1.16 | |

|  | |

| Figure 1.16: Library Graphics Example | |

| # 1.4.4 Loadflow Graphics | |

| 1.4.4 Loadflow GraphicsThis section is applicable for power system components only. Control components do not participate in the loadflow so this section will remain blank for control components. | |

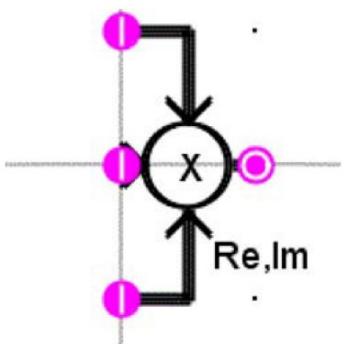

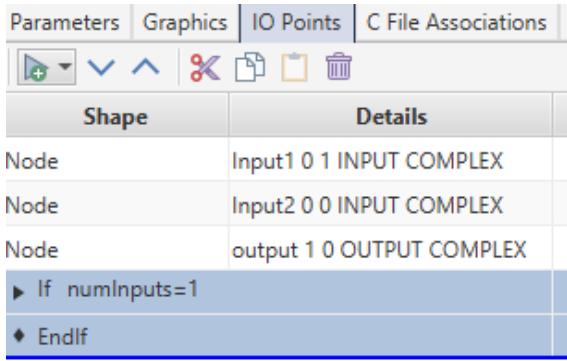

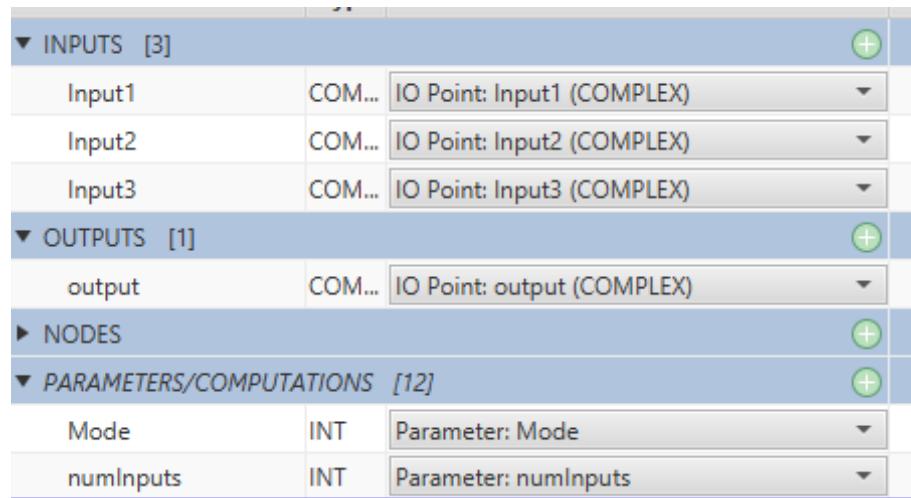

| # 1.5 ADD THE IO POINTS | |

| In this example some of the IO points are conditional. | |

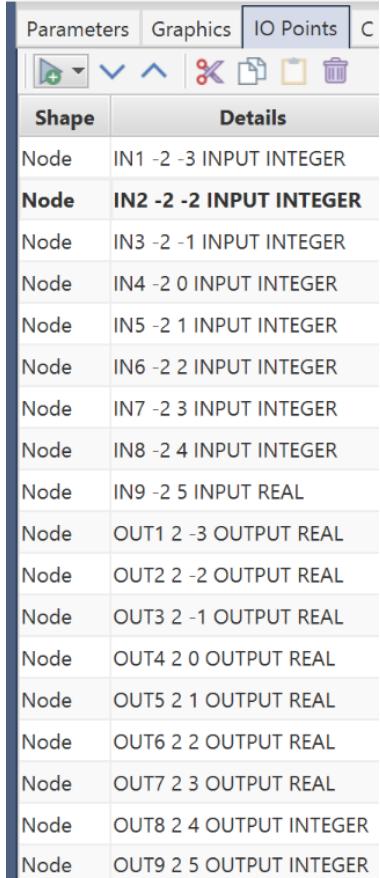

| Select the 'IO Points' tab. | |

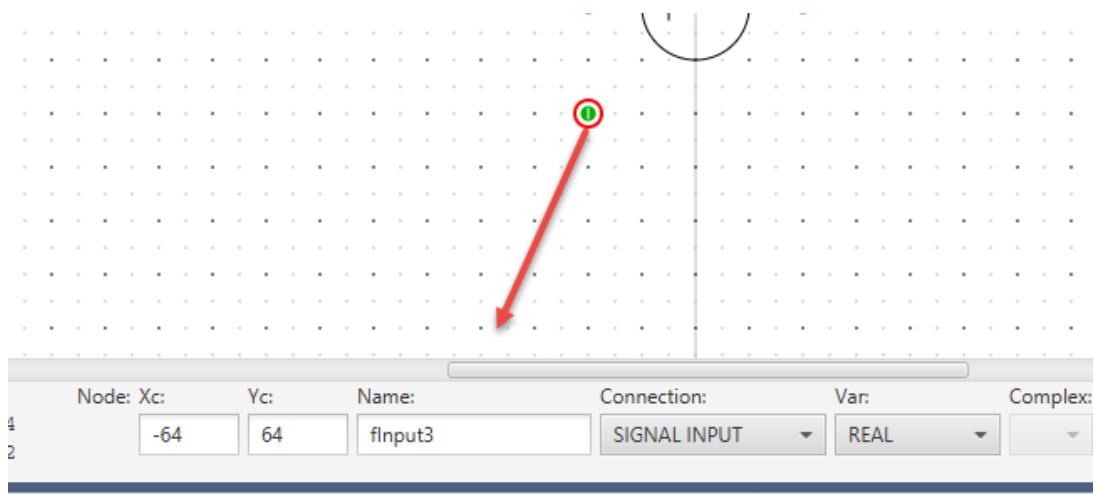

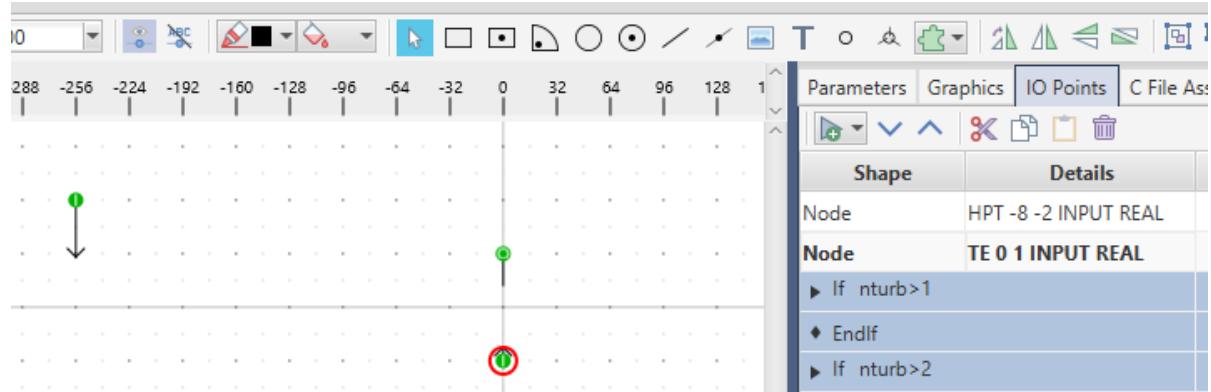

| Add 3 nodes using the 'Draw Node' button from the toolbar, Clicking twice on the button will allow several nodes to be drawn successively. Place two of the nodes at the first 2 inputs, place the third at the output of the component. Node details can be modified by selecting each node and editing the information box that appears below the graphics window. See Figure 1.17. | |

|  | |

| Figure 1.17: Adding Node Information | |

| The information for the IO nodes are listed below. | |

| # IO point flnput1 | |

| <table><tr><td>Name</td><td>flnput1</td></tr><tr><td>Type</td><td>SIGNAL INPUT</td></tr><tr><td>Data Type</td><td>REAL</td></tr></table> | |

| # IO point flnput2 | |

| <table><tr><td>Name</td><td>flnput2</td></tr><tr><td>Type</td><td>SIGNAL INPUT</td></tr><tr><td>Data Type</td><td>REAL</td></tr></table> | |

| # IO point fOutput | |

| <table><tr><td>Name</td><td>fOutput</td></tr><tr><td>Type</td><td>SIGNAL OUTPUT</td></tr><tr><td>Data Type</td><td>REAL</td></tr></table> | |

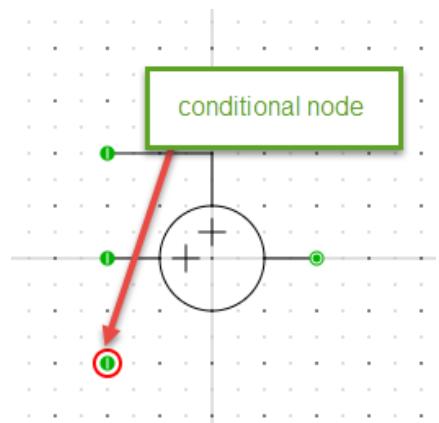

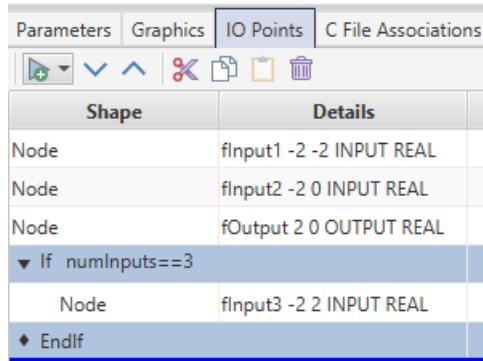

| Inside the IO tab, create an 'If' condition and enter 'numInputs $= = 3^{\prime}$ as the condition. | |

| Select the condition 'If numInputs $= = 3^{\prime}$ to ensure the insertion point is inside the condition and add the flnput3 IO point (input to sign3). | |

|  | |

| Figure 1.18: Adding Conditional Graphics | |

| # IO point fInput3 | |

| <table><tr><td>Name</td><td>flnput3</td></tr><tr><td>Type</td><td>SIGNAL INPUT</td></tr><tr><td>Data Type</td><td>REAL</td></tr></table> | |

| The IO tab should now appear as shown in Figure 1.19. | |

|  | |

| Figure 1.19: Creating Conditions in IO Points Tab | |

| # 1.6 ADDING THE MODEL CODE | |

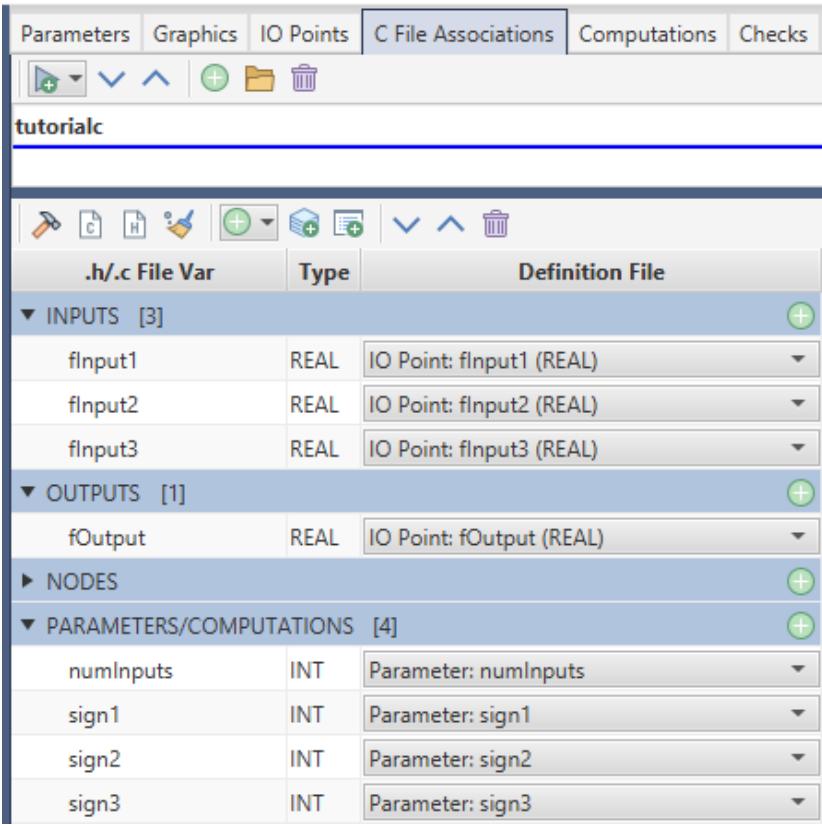

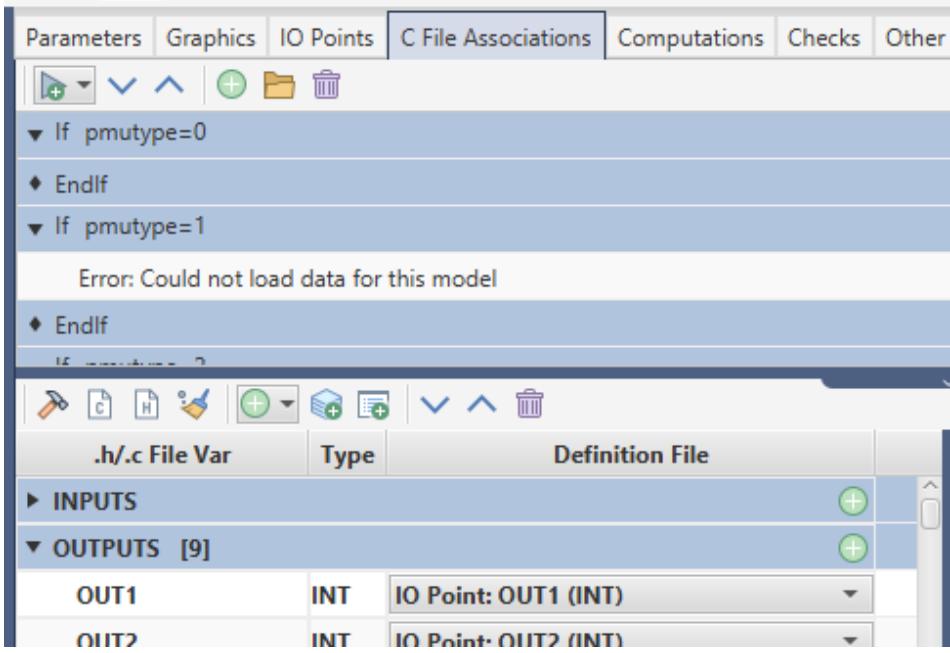

| - Select the 'C File Associations' tab.- Select the + icon to Add New Association.- Enter a model name such as 'tutorialc'- The associations should appear similar to Figure 1.20. | |

|  | |

| Figure 1.20: Adding a New Association | |

| - The input and output points appear under the 'INPUTS' and 'OUTPUTS' sections and not the 'NODES' section. This is a controls component and the NODES section is reserved for power system component electrical type nodes.- The next step is writing the c-code which defines the behaviour of the component. Select the $\square$ icon to begin editing the .c file.Simple 'c' code to add two inputs together and produce an output might look something like the following: | |

| CODE: fOutput $=$ fInputl $^+$ fInput2; | |

| - Type the c-code listed in Section 1.7 into tutorialc.c then push the compile icon in the C File Association tab, to compile the code. If the compile is successful, the component is ready to be included in a Draft circuit.- Ensure that the CBuilder component is saved.- Draft has an internal memory of the components used during a draft session. If a component icon is modified while Draft is open, the icons must be refreshed. Select the $\square$ icon from the library toolbar to refresh components. | |

| # 1.7 SAMPLE 'C' CODE FOR THE MULTIPLE INPUT ADDER | |

| Note: The code should not be copy pasted due to encoding issue. The user should write the code in their editor. | |

| # Code is shown below: | |

| include "tutorialc.h" | |

| STATIC: // use the mult variables to keep track of sign of input int multl; int mult2; int mult3; | |

| # RAM: | |

| // the parameters signl, sign2 and sign3 are toggles where // $0 = =$ plus and $\mathrm{\bf 1} = =$ minus // use the mult variables to keep track of sign of input if $\mathrm{\bf sign1} = =\mathrm{\bf 1}$ | |

| mult1 = - 1; else mult1 = 1; if (sign2 == 1) mult2 = - 1; else mult2 = 1; if (sign3 == 1) mult3 = - 1; else mult3 = 1; | |

| CODE: | |

| if (numInputs > 2) fOutput = (mult1 * fInput1) + (mult2 * fInput2) + (mult3 * fInput3); else fOutput = (mult1 * fInput1) + (mult2 * fInput2); | |

| # 2 INTEGRATOR | |

| # 2.1 INTRODUCTION | |

| The integrator reads in one real input, integrates the input with a user specified time- constant (T) and writes one output. The basic equations, based on trapezoidal rule of integration with a simulation time- step of $\Delta t$ , are used to compute the integral of the input as shown in Equation 2- 1, Equation 2- 2, Equation 2- 3, and Equation 2- 4. | |

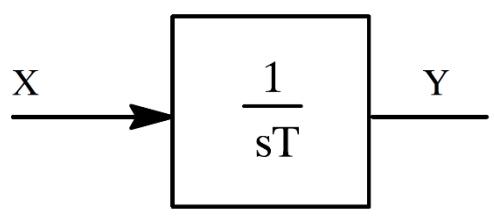

|  | |

| Figure 2.1: Basic Integral | |

| $$ | |

| Y(t) = \frac{1}{T}\int X(t)dt | |

| $$ | |

| Equation 2- 1 | |

| $$ | |

| Y(t) = \frac{1}{T}\int_{t - \Delta t}^{t}X(t)dt + Y(t - \Delta t) | |

| $$ | |

| Equation 2- 2 | |

| $$ | |

| Y(t) = \frac{1}{T}\left\{\frac{\Delta t*[X(t - \Delta t) + x(t)]}{2}\right\} +Y(t - \Delta t) | |

| $$ | |

| Equation 2- 3 | |

| $$ | |

| Y(t) = \frac{\Delta t}{2T}\{X(t - \Delta t) + x(t)\} +Y(t - \Delta t) | |

| $$ | |

| Equation 2- 4 | |

| # Data Preparation: | |

| Initialize Xold $= 0.0$ Initialize Yold $= 0.0$ Compute $k = dt / (2T)$ | |

| # Algorithm: | |

| Read X; $\mathsf{Y} = \mathsf{K}^{\ast}(\mathsf{Xold} + \mathsf{X}) + \mathsf{Yold};$ Write Y; | |

| # 2.2 DRAW GRAPHICS AND ADD PARAMETERS | |

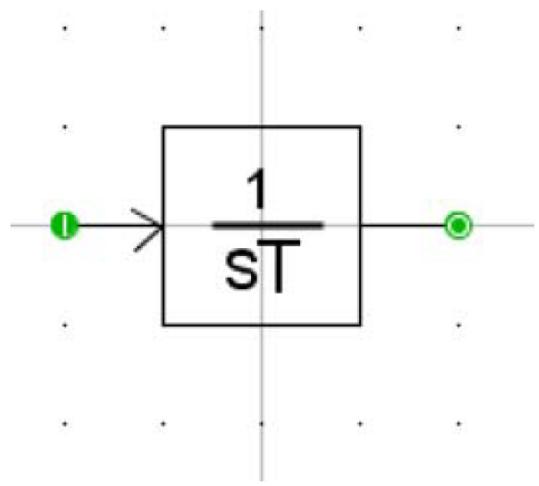

| Draw an icon that looks similar to Figure 2.2. | |

|  | |

| Figure 2.2: Integrator Component Icon | |

| The component icon for the integrator includes two I/O points. One signal input named input and one signal output named output, both are real.- | |

| Add a parameter 'T' to specify the time constant (type REAL). | |

| # 2.3 ADDING THE MODEL CODE | |

| Select the 'C File Associations' tab.- Select the "Add new Association" which is a plus sign on a green circle.- Enter the model name as "integrate".- Select the "Edit C File" to write the code. | |

| Input and Output points (listed under the IO Points tab) and user defined parameters (listed under the Parameters tab) are automatically associated with the model and placed in the .h file. Left clicking the "View .h file" button opens the .h file in an editor. A model that includes one input, one output and a parameter would have the following lines in the .h file: | |

| INPUTS: double input; OUTPUTS: double output; | |

| # PARAMETERS: | |

| double T; | |

| # 2.4 SAMPLE 'C' CODE FOR AN INTEGRATOR | |

| include "integrate.h" | |

| # STATIC: | |

| /* * Variables declared here may be used in both the */ /* RAM: and CODE: sections below. */ /* double dt; double input_old, output_old, K; /* - E n d o f S T A T I C : S e c t i o n - */ | |

| # RAM: | |

| /* Place C code here which computes constants */ /* required for the CODE: section below. The C */ /* code here is executed once, prior to the start */ /* of the simulation case. */ /* dt= getTimeStep(); input_old = 0.0; output_old = 0.0; K = dt / (2.0 * T); */ | |

| /* - - - - E n d o f R A M : S e c t i o n - - - - */ | |

| CODE: /* */ /* Place C code here which runs on the RTDS. The */ /* code below is entered once each simulation */ /* step. */ /* output = (input + input_old) * K + output_old; input_old = input; output_old = output; | |

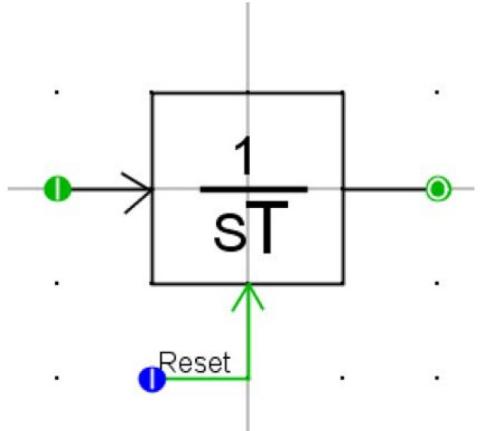

| # 2.5 ADD A RESET INPUT TO THE INTEGRATOR | |

| Add shapes to the icon to include a reset input. | |

|  | |

| Figure 2.3: Adding Reset Input to Integrator | |

| - Add an integer I/O point named reset to the reset input.- Update the association to include the new I/O point.- Modify the 'C' code to reset the integrator when a value other than 0 is applied to the reset input.- Recompile the new code.- Save the new icon. | |

| CODE: | |

| if (reset != 0) { | |

| # Builder Tutorial: Integrator | |

| output $= 0$ input_old $= 0$ output_old $= 0$ } else { output $=$ input $^+$ input_old) \* K $^+$ output_old; input_old $=$ input; output_old $=$ output; } | |

| Draft has an internal memory of the components used during a draft session. If a component icon is modified while Draft is open, the icons must be refreshed. Select the $\odot$ icon from the Draft toolbar to refresh components. | |

| Note: Compile the model. The component is now ready. Make sure to save the file. User can load it in RSCAD and test out the component. In order to load the component in RSCAD, right click on a an empty spot in draft, and select Add Component > User > load the definition file. | |

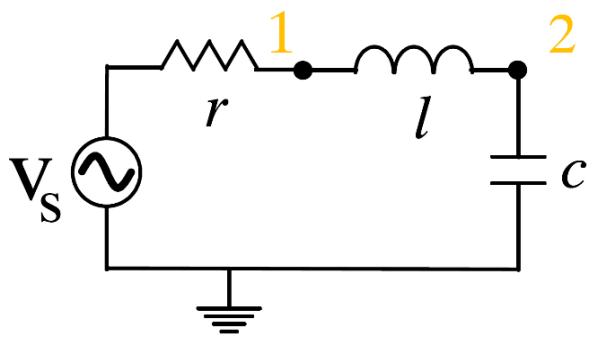

| # 3 VARIABLE CAPACITOR | |

| # 3.1 INTRODUCTION | |

| This component will be modeled as a power system component in CBuilder. | |

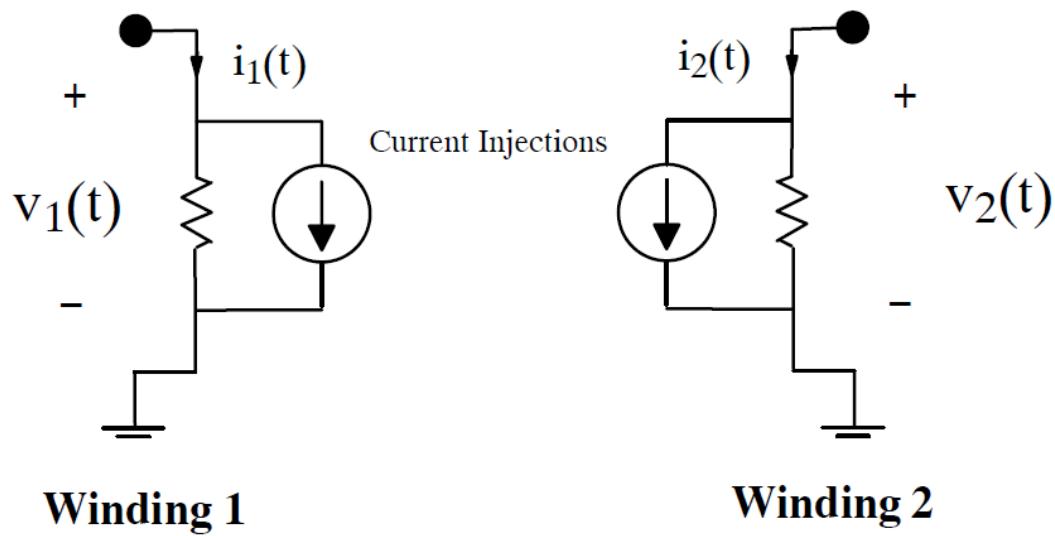

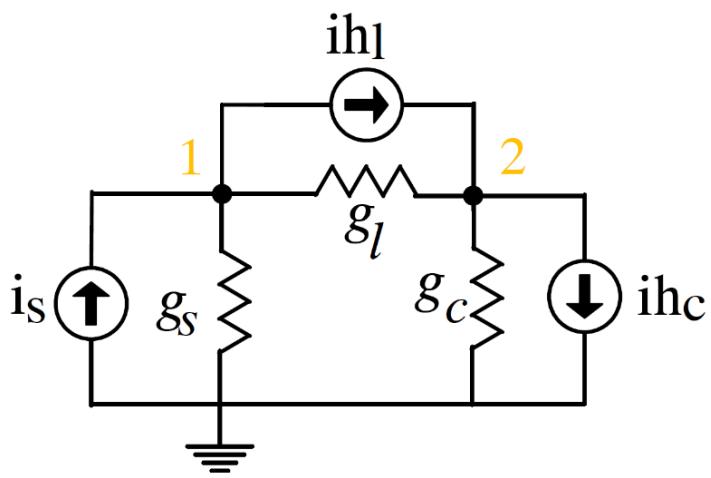

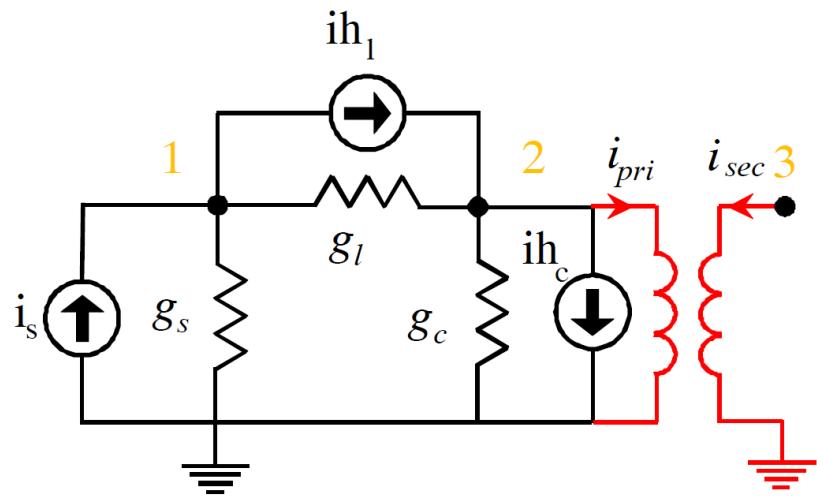

| Control system components interact with other components using control type input and output signals and do not interact directly with the solution of the power system network. Power system components, on the other hand, need to interact directly with the solution of the power system network. The interface is usually made by specifying an impedance at the nodes to which the component is connected and by providing current injections into those nodes. | |

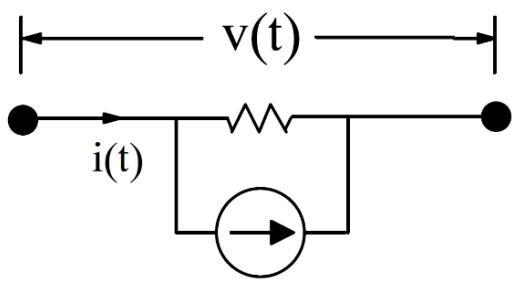

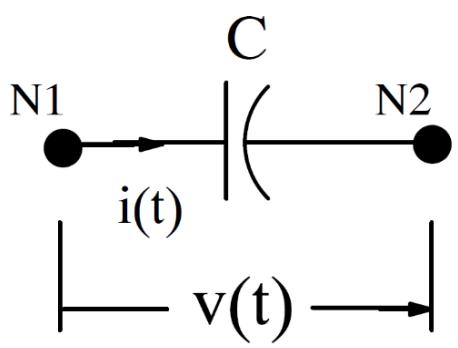

|  | |

| Figure 3.1: Current Injection | |

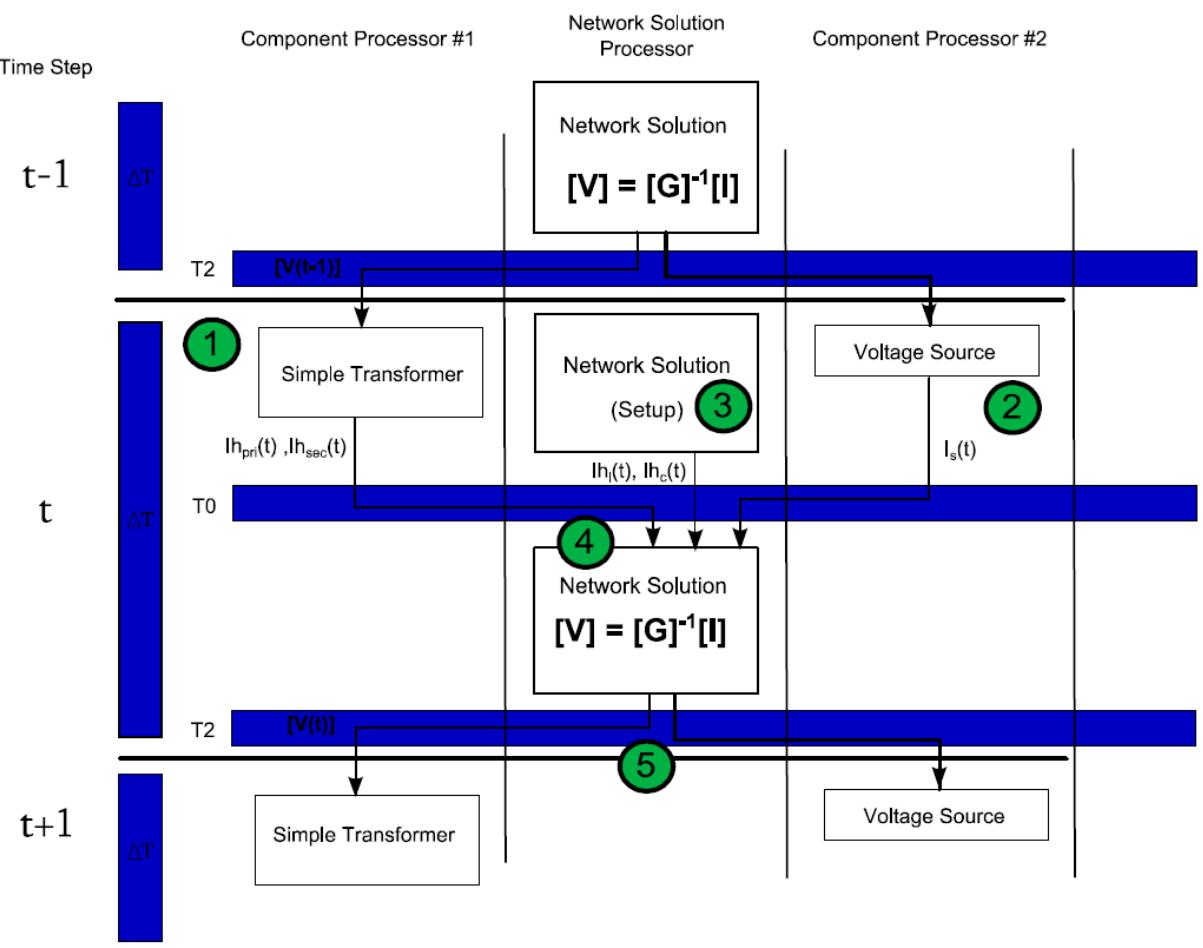

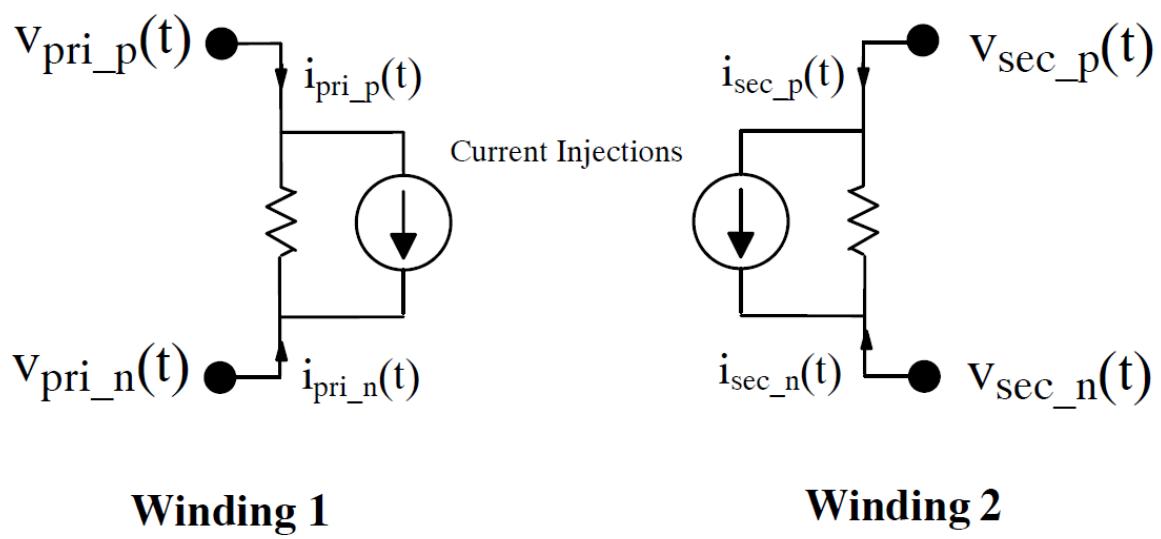

| The network solution expects to receive current injection values from power system components well before the end of the simulation time- step so that there is enough time remaining in the time- step to compute the new node voltages. To accommodate this, the CODE: section for power system components is divided into two portions Begin- T0 and T0- T2. | |

| The first portion, referred to as Begin- T0, is used to execute the statements required to compute current injections which the component injects into the nodes to which it is connected. Once the current injections are ready, the executable code is suspended until all of the other power system models have completed their current injection calculations. At this point the current injections from all of the power system models allocated to the RTDS rack are sent to the processor/core dedicated to solving the power system network. Upon completion of this T0 transfer, executable code for the components who participated in T0 continues. The remaining portion of the executable code, referred to as T0- T2 may be used to solve portions of the algorithm that are not needed to compute the current injections, for preparing variables that are written out for monitoring and preparing for the next time- step. | |

| Once the second portion of code is completed the executable code is again suspended until all of the variables transferred during the T2 communication interval have been transferred between processors. Control type variables, monitored variables and node voltages are exchanged during the T2 communication interval. The node voltages are computed by the processor allocated to the network solution and transferred to other processors in the rack. As such, new node voltage data is available once the processors are restarted for the next simulation time- step. | |

| # 3.2 CAPACITOR | |

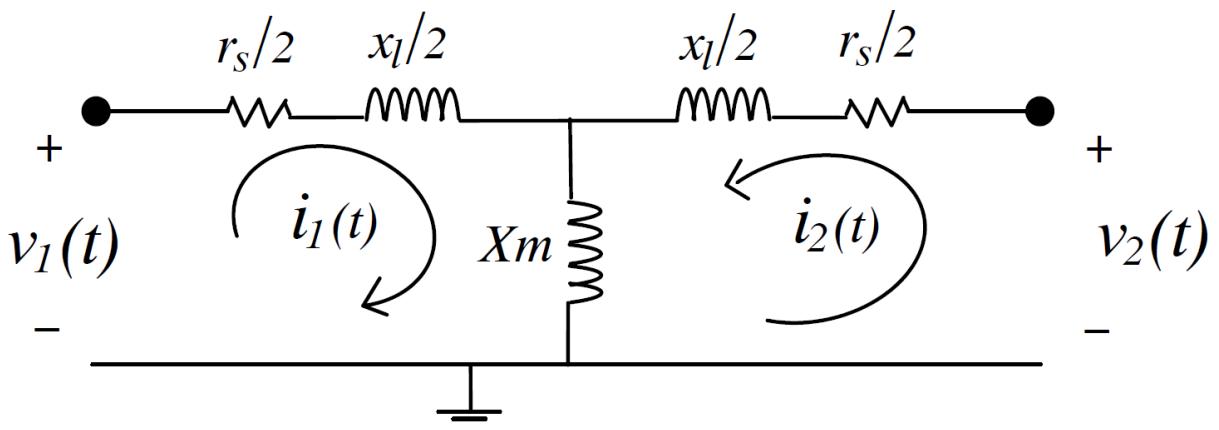

| Application of the trapezoidal rule of integration to the basic capacitor equation is used for the numerical solution of the capacitor. | |

|  | |

| Figure 3.2: Simple Capacitor | |

| $$ | |

| V(t) = V_{N1}(t) - V_{N2}(t) | |

| $$ | |

| $$ | |

| i(t) = C*\frac{dV(t)}{dt} | |

| $$ | |

| $$ | |

| V(t) = \frac{1}{C}\int i(t)dt | |

| $$ | |

| Equation 3- 1 | |

| Equation 3- 2 | |

| Equation 3- 3 | |

| $$ | |

| V(t) = \frac{1}{C}\int_{t - \Delta t}^{t}i(t)dt + V(t - \Delta t) | |

| $$ | |

| Equation 3- 4 | |

| Applying trapezoidal rule of integration results in Equation 3- 5. | |

| $$ | |

| i(t) = \frac{2C}{\Delta t} *V(t) - \frac{2C}{\Delta t} *V(t - \Delta t) - i(t - \Delta t) | |

| $$ | |

| Equation 3- 5 | |

|  | |

| Figure 3.3: IH: Current Injection | |

| Define: | |

| $$ | |

| IH(t) = -\frac{2C}{\Delta t} *V(t - \Delta t) - i(t - \Delta t) | |

| $$ | |

| $$ | |

| i(t) = \frac{2C}{\Delta t} *V(t) + IH(t) | |

| $$ | |

| Equation 3- 6 | |

| Equation 3- 7 | |

| # 3.3 DRAW GRAPHICS AND ADD PARAMETERS | |

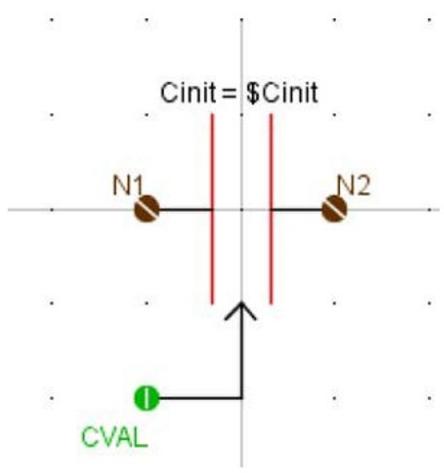

| Draw a capacitor icon similar to that shown in Figure 3.4. | |

|  | |

| Figure 3.4: Capacitor Icon | |

| The component icon for the variable capacitor includes two power system nodes and one signal input as shown in Figure 3.4. The signal input 'CVAL' is used to read in variable capacitance values. | |

| Add a parameter 'Cinit' to specify the initial value of capacitance. | |

| A power system node is created by creating an I/O Point/Node and selecting "PSYS Node" as the connection type. | |

| # 3.4 ADDINGTHEMODELCODE | |

| Select the 'C File Associations' tab.- Select the icon to Add New Association.Creating the C File Associations for the component automatically generates the following associations: | |

| INPUTS: CVAL, capacitance value signal input | |

| NODES:N1,N2 power system nodes | |

| PARAMETERS:Cinit, initial value of capacitance | |

| In addition to those listed above, the following additional associations need to be made: | |

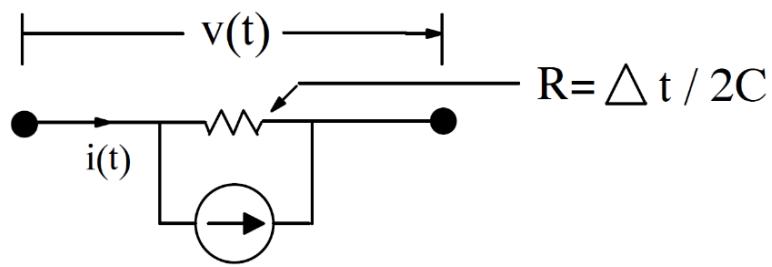

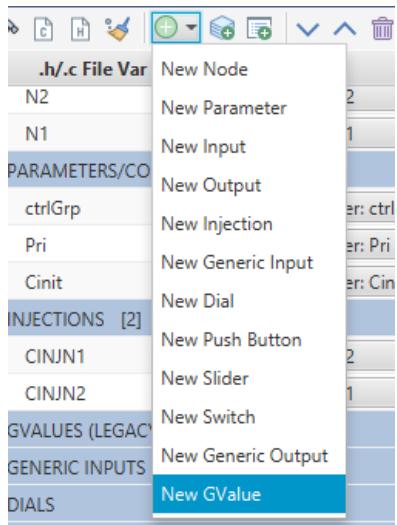

| GVALUES: A conductance value (1/R) that the component places between the nodes to which it is connected. Recall, that the representation of the capacitor requires a resistor equal to $\Delta t / (2C)$ to be placed between the nodes to which the component is connected. The equivalent conductance is equal to $1 / R = 2C / \Delta t$ . To add the GVALUE association select the Add Variable to .h File "+" button from the C File Associations Tab and select New GValue. Edit new gvalue window will appear at the right hand side when the gvalue line is selected. Type will be Real and enter the variable name to which the conductance value will be assigned in the .c code. | |

|  | |

| Figure 3.5: Adding Gvalues to Power System Model | |

| INJECTIONS: The capacitance model injects current into node2 and out of node1. To add an injection, click the + on the injections section. Type: REAL. Enter the name for the current injection variable (CINJN1). Select the down arrow icon for the | |

| CINJN1 variable and select Node N1. Add another current injection variable (CINJN2) and associate it with Node N2. | |

| <table><tr><td colspan="3">INJECTIONS [2]</td></tr><tr><td>CINJN1</td><td>REAL</td><td>Node: N1</td></tr><tr><td>CINJN2</td><td>REAL</td><td>Node: N2</td></tr></table> | |

| - Selecting File->Save causes the newly added GVALUES and INJECTIONS variables to be written to the .h file so they can be accessed in the .c file. | |

| - Write the 'c' code. Select the icon to edit the .c file. | |

| Basic Algorithm: | |

| Read 2 node voltages v1(t), v2(t) Compute $\mathsf{V}(\mathsf{t}) = \mathsf{v}1(\mathsf{t}) - \mathsf{v}2(\mathsf{t})$ Compute branch current: $\mathsf{i}(\mathsf{t}) = 2\mathsf{C} / \Delta \mathsf{t}^{*}\mathsf{V} + \mathsf{IH}(\mathsf{t} - \mathsf{dt})$ note: IH(t) from previous time- step Read Capacitance Value Compute $\mathtt{Gc} = 2\mathtt{C} / \Delta \mathtt{t}$ Set new Gc value for network solution Compute Injection Current: $\mathsf{IH}(\mathsf{t}) = - 2\mathsf{C} / \Delta \mathsf{t}^{*}\mathsf{V} - \mathsf{i}(\mathsf{t})$ Set injection current for node1 and node2 | |

| The RAM section initializes the history term current IH(t- dt) to 0.0 and computes the constant 1/Δt for use in the CODE: section. | |

| Static: double dt, invdt, Ih, Gcap, Vbra, ib; | |

| RAM: dt $=$ getTime- step(); invdt $=$ 1.0/dt; $\mathbb{I}\mathfrak{h} = \mathbb{0},\mathbb{0}$ . Gcap $=$ 2.0 \* Cinit \* 1.0e- 6 \* invdt; | |

| The CODE: section computes the branch current for the capacitor, the new conductance for the capacitance and the current injections into the nodes between which the component is connected. All of the code is assigned to the BEGIN_TO portion since it is required to compute the injection currents. The capacitance value is read in as micro- farads (i.e. 1.0 is interpreted as 1.0e- 6 farads) so the CVAL variable must be multiplied by 1.0e- 6 before it can be used. | |

| CODE: | |

| BEGIN_T0: | |

| /* Compute branch current */ Vbra = N1 - N2; ib = Gcap * Vbra + Ih; | |

| /* Compute new value of Cfarad */ Gcap = 2.0 * CVAL * 1.0e- 6 * invdt; GCVAL = Gcap; | |

| /* Compute new History Current */ Ih = - Gcap * Vbra - ib; | |

| /* Write current injections into N1, N2 */ /* +ve means current out of node */ CINJN1 = Ih; CINJN2 = - Ih; | |

| # 3.5 ADDING AN OPTIONALLY MONITORED VARIABLE | |

| It is often desirable to permit the user to optionally monitor various internal variables associated with a component. Monitoring of such internal variables may be useful for debugging when the component is part of a larger control circuit. The monitoring may be included without adding additional output points to the component. The following procedure is suggested: | |

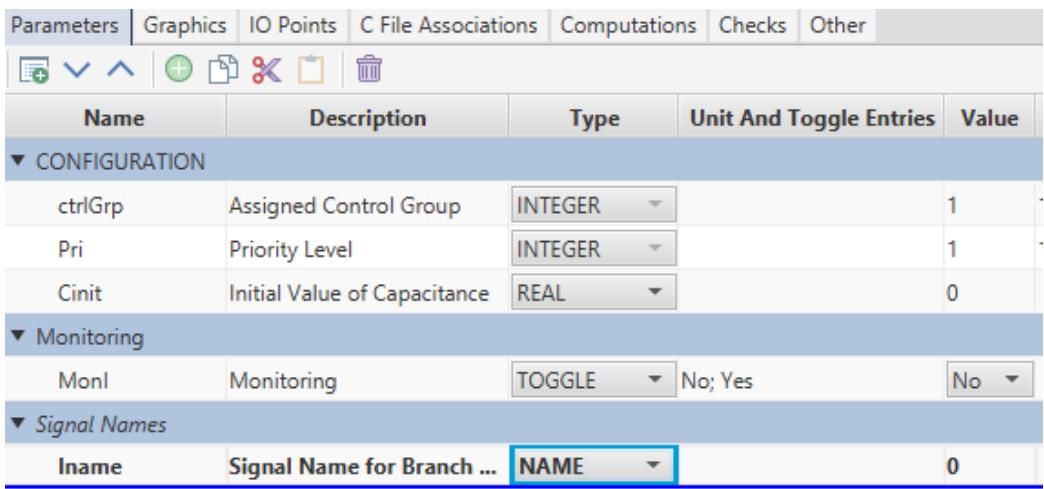

| 1. Add a Yes/No Toggle type parameter which permits the user to select whether the current is to be monitored in a new section called "MONITORING". (see 1 of Figure 3.6). | |

| 2. Add a Name type parameter which permits the user to enter a name for the monitored | |

| current. The Name entry can be made conditional on the monitoring being enabled in a new section called "Signal Names" (see 2 of Figure 3.6). | |

| 3. Add a new generic output variable which is active only if the monitoring is enabled in the C File Association. | |

| 4. Add statements to the RTDS C code to assign the branch current to the monitored variable. | |

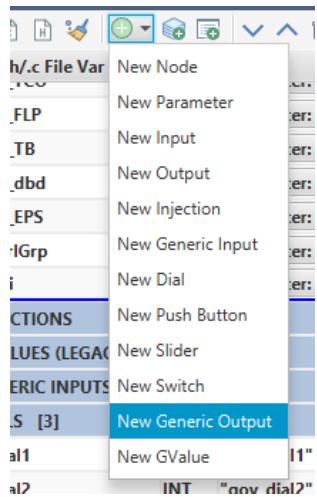

|  | |

| Figure 3.6 Adding a Monitored Variable in CBuilder | |

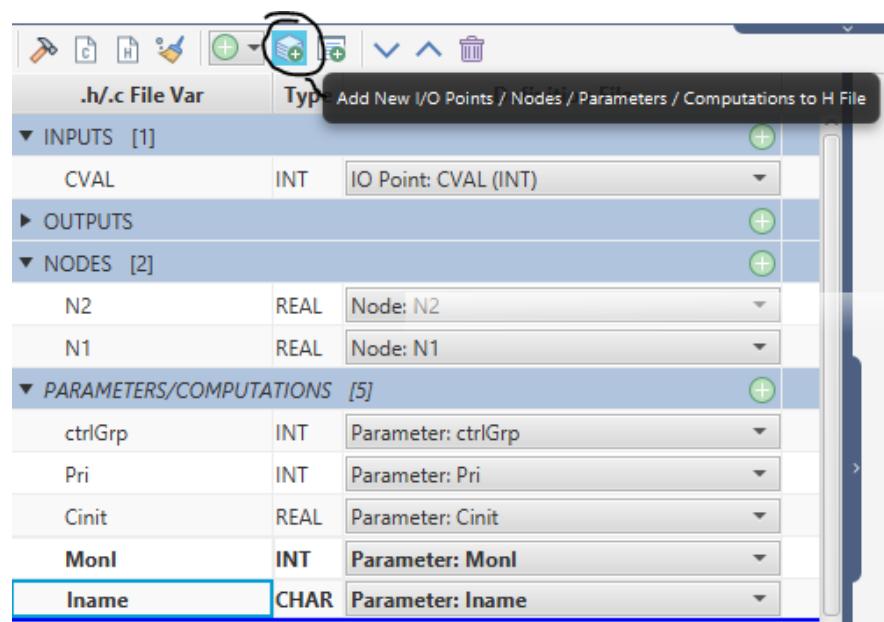

| The new parameters Monl and Iname must be added to the .h file. Select the Add New IO Points/Nodes/Parameters/Computations to Association icon from the C File Associations tab to add these new parameters. | |

|  | |

| Figure 3.7: Adding New IO Points to C File Association | |

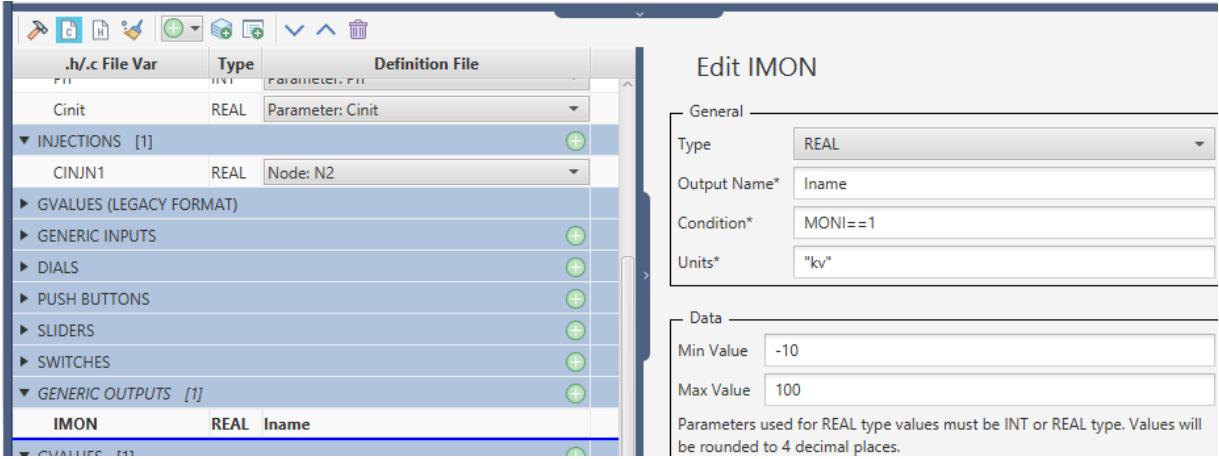

| To add the monitored variable parameter to the .h file, left click the Add Variable to .h File button under the C File Associations tab. Select create: Generic Outputs from the pulldown menu associated with the Section: field and set Type: to REAL. Enter a variable name (e.g. IMON) to be used for assignment of the monitored variable in the .c file. After selecting OK, the Edit Output menu appears in which additional parameters for the output variable may be specified. | |

|  | |

| Figure 3.8: Editing The Generic Output Section | |

| Type: REAL H File VAR: IMON Output Name: iname Group: "Branch Currents" Min Value: - 100.0 Max Value: +100.0 Unit: "kA" Condition: Monl=+1 | |

| Min and Max values are used as the default limits for a meter or plot component assigned to display the signal specified by Output Name. The specified unit name also appears on the meter or plot component in RSCAD/RunTime. | |

| The create: OUTPUTS data line for the monitored output variable appears as: | |

|  | |

| Figure 3.9: Creating a Generic Output | |

| "1" is the parameter name for .c file.- "2" is the signal name available in RSCAD/RunTime. | |

| The C code statement to write out the monitored variable is as follows: | |

| IMON = ib;- The current monitoring should be assigned in the T0_T2 section of the CODE. | |

| # 4 MULTI-MASS SYSTEM | |

| # 4.1 INTRODUCTION | |

| Representation of the mechanical characteristics of turbine generator units in electromagnetic transients programs is necessary if the interaction between the electrical system and mechanical system is to be studied. In some situations a resonant condition may exist between the electrical system and the mechanical system which can lead to torsional oscillations which stress the mechanical couplings between the various turbines and between the turbine and generator. Perhaps the best documented case of such a resonance was at the Navajo Project, a coal fired generation unit located in northern Arizona, U.S.A. [1]. Data from the Navajo Project was used to develop a first and second benchmark model for torsional oscillations [2],[3]. | |

| This document outlines how the mechanical characteristics of a turbine- generator system may be incorporated into a model for use on the RTDS. Once the equations for the multi- mass system have been developed, the procedure for implementing the corresponding algorithm using the CBuilder feature under RSCAD is documented. | |

| Development of the equations representing the mechanical system follows that presented in Kundar [4]. Firstly, the equations of motion for a single mass rotating about an axis are developed. The analysis is then expanded to account for two masses connected by a shaft and finally generalized to multiple masses. | |

| # 4.2 SINGLE MASS ROTATING ABOUT AND AXIS | |

| # 4.2.1 EQUATIONS OF MOTION REPRESENTING A SINGLE MASS ROTATING ABOUT AN AXIS | |

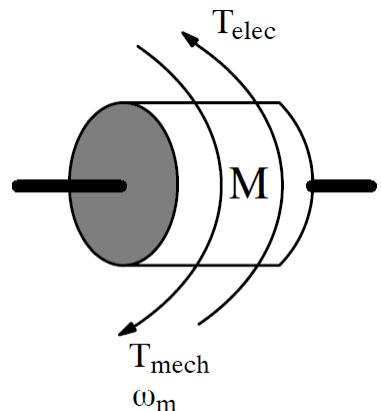

|  | |

| Figure 4.1: Single Mass Rotating Motion | |

| The basic equation of motion for a rotating mass stems from Newton's Second Law of motion (commonly stated as $F = mA$ ) where the Force is the difference between the mechanical torque applied by a turbine and the electrical torque applied across the air- gap of the generator. Acceleration for the rotating mass is the rate of change of its rotational speed $(\omega_{m})$ . Instead of the mass of the rotating body, the mass' moment of inertia (J) is used. The moment of inertia considers both the rotating body's mass and its distribution around the axis of rotation. | |

| $$ | |

| J\frac{d\omega_{m}}{dt} = T_{m - }T_{e} \tag{[1]} | |

| $$ | |

| J Mass' moment of Inertia in $\mathsf{kg}\cdot \mathsf{m}^2$ $\omega_{m}$ rotational speed of the mass in mech. rad/sec $T_{m}$ Mechanical torque applied by the turbine $(N\cdot m)$ $T_{e}$ Electrical torque applied by the generator $(N\cdot m)$ $(1N = 1kg\cdot m / sec^2)$ | |

| It is important to note that $\omega_{m}$ in [1] above represents the mechanical rotational speed of the machine in rad/sec. It is to be differentiated from the machine's electrical rotational speed. Mechanical speed and electrical speed is the same for a machine with only one pole pair. Machines that have more than a single pole pair will have a slower mechanical rotational speed than one with just one pole pair. | |

| $$ | |

| \omega_{e} = \omega_{m}*n | |

| $$ | |

| By using the per- unit inertia constant, H, which is defined as the mass' kinetic energy in watt- seconds at rated speed, as opposed to the moment of inertia, equation [1] can be expressed in terms of electrical rad/sec. H and J are related as - | |

| $$ | |

| \begin{array}{c}{H = \frac{1}{2}\frac{J\omega_{0m}^2}{VA_{base}}}\\ {J = 2\frac{H}{\omega_{0m}^2} VA_{base}} \end{array} \tag{2} | |

| $$ | |

| $\omega_{0m}^{2}$ rated rotational speed of the mass in mechanical rad/sec. $VA_{base}$ Volt- Amp base for the system | |

| Substituting [2] into [1] yields - | |

| $$ | |

| \frac{2H}{\omega_{0m}^2} VA_{base}\frac{d\omega_m}{dt} = T_m - T_e \tag{3} | |

| $$ | |

| Noting that - | |

| $$ | |

| \begin{array}{c}{\omega_{m} = \omega_{r} = \omega_{pu}}\\ {\omega_{0m} = \omega_{0}}\\ {T_{base} = \frac{VA_{base}}{\omega_{0m}},\frac{T}{T_{base}} = T_{pu}} \end{array} \tag{5} | |

| $$ | |

| $\omega_{r}$ rotational speed of the mass in electrical rad/sec $\omega_{0}$ rated rotational speed of the mass in electrical rad/sec. $T_{base}$ base value of mechanical torque we re- arrange equation [3] such that equations [4] and [5] may be substituted. | |

| $$ | |

| \begin{array}{c}{2H\frac{d}{dt}\left[\frac{\omega_m}{\omega_{0m}}\right] = \frac{T_m - T_e}{VA_{base} / \omega_{0m}}}\\ {2H\frac{d}{dt}\left[\frac{\omega_r}{\omega_0}\right] = \frac{T_m - T_e}{VA_{base} / \omega_{0m}}}\\ {2H\frac{d}{dt}\left[\frac{\omega_r}{\omega_0}\right] = \frac{T_m - T_e}{T_{base}}} \end{array} \tag{8} | |

| $$ | |

| Equation [8] above relates the per- unit applied torque to the per- unit rotational speed of the mass. Implementation of equation [8] into the the RTDS solution algorithm may be done by applying trapezoidal rule to yield - | |

| $$ | |

| 2H\frac{\omega_{pu(t)} - \omega_{pu(t - \Delta t)}}{\Delta t} = \frac{T_{apu(t)} + T_{apu(t - \Delta t)}}{2} \tag{9} | |

| $$ | |

| $T_{a_{pu}}$ per- unit accelerating torque | |

| $$ | |

| T_{a_{pu}} = (T_m - T_e) / T_{base} | |

| $$ | |

| At the beginning of the simulation time- step all of the quantities in [9] listed as functions of $(t - \Delta t)$ are known, as are the constants $2H$ and $\Delta t$ . The most recently computed value of $T_{a_{pu}}$ is used as $T_{a_{pu}(t)}$ . This leaves only $\omega_{pu(t)}$ to be computed. | |

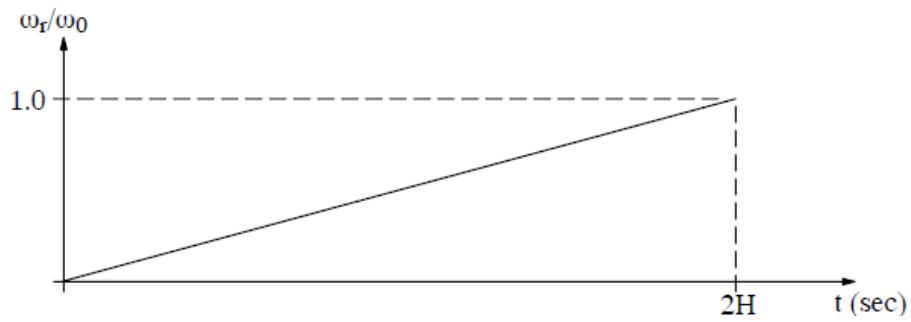

| To demonstrate the action of [9], we can apply a constant 1 per- unit torque with no electrical torque (ie. open circuit conditions for a frictionless generator) and note that the mass' speed linearly increases. Under such conditions the rotating mass reaches 1 per- unit rotational speed after $2H$ seconds. $2H$ is referred to as the mechanical starting time. | |

|  | |

| Figure 4.2: Mechanical Starting Time | |

| # 4.3 DAMPING | |

| In the equations for the rotating mass described above, there was no consideration of damping. Removing the applied torque in the example above results in the mass rotating at $\omega_{pu}$ indefinitely. In [4] a damping term proportional to $\Delta \omega_r$ is introduced. Adding such a term to [8] yields - | |

| $$ | |

| 2H\frac{d}{dt}\left[\frac{\omega_r}{\omega_0}\right] = \frac{T_m - T_e}{T_{base}} -D\Delta \left[\frac{\omega_r}{\omega_0}\right] \tag{[10]} | |

| $$ | |

| Damping proportional to speed deviation (ie. $D\Delta \left[\frac{\omega_r}{\omega_0}\right]$ ) results in an accelerating torque when the speed of the rotating mass is less than the rated speed. Such a representation is reasonable for small perturbations of speed around the rated speed. However, if the mass is to be used as part of a generator - turbine model which is required to have large deviations from synchronous speed, the chosen representation of damping leads to unrealistic behavior. Take for instance the case where the generator is to be started from standstill. At | |

| zero speed the speed deviation is - $1_{pu}$ and according to [10] the mass is subjected to an accelerating torque of $+D_{pu}$ . | |

| A physical interpretation of the damping term proportional to speed deviation is given in the discussion to reference [5]. | |

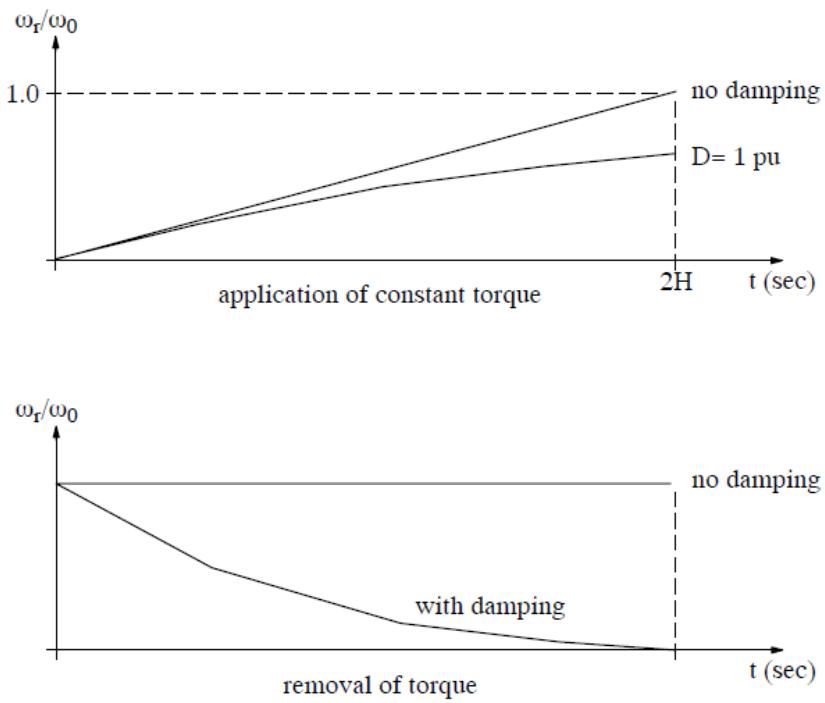

| A damping term proportional to per- unit speed, representing the friction and windage losses, can be introduced into [8] to obtain [1]. The addition of a speed proportional damping term changes the response of the mass to a constant mechanical torque input as shown in Figure 4.3 (compare with Figure 4.2 which shows the response with no damping term). | |

| $$ | |

| 2H\frac{d}{dt}\left[\frac{\omega_r}{\omega_0}\right] = \frac{T_m - T_e}{T_{base}} -D\left[\frac{\omega_r}{\omega_0}\right] \tag{[11]} | |

| $$ | |

|  | |

| Figure 4.3: Response With Speed Proportional Damping | |

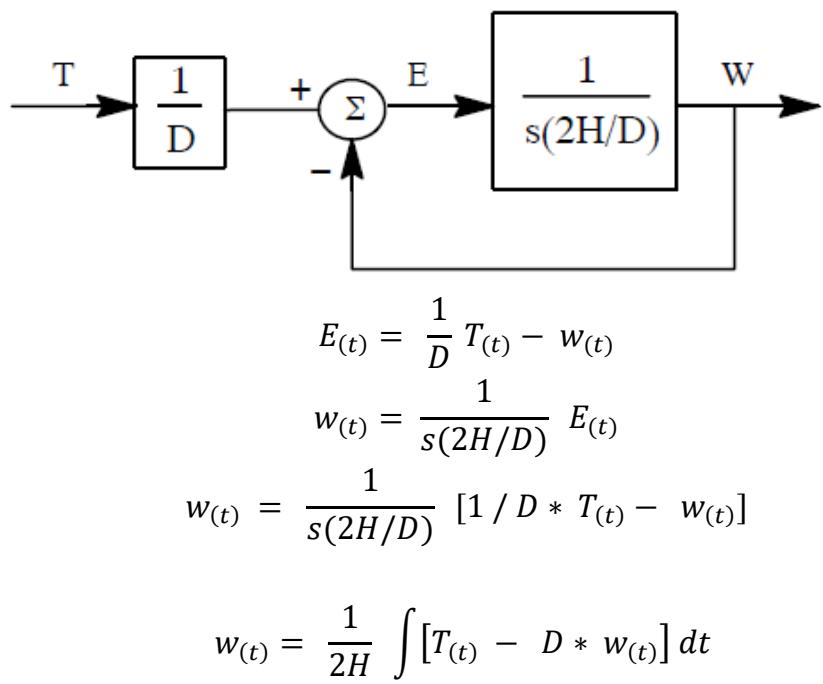

| Removal of the applied torque, using [11] to represent the rotating mass, results in the mass' rotational speed slowing to 0.0. Note that equation [11] has the same form as a first order lag with a gain of $1 / D$ and a time- constant of $2H / D$ seconds. | |

|  | |

| 1st order lag function with $\text{Gain} = 1 / D$ and time constant $= 2H / D$ . Compare with equation [11] above. | |

| # 4.4 TWO ROTATING MASSES COUPLED BY A SHAFT | |

| 4.4.1 EQUATIONS OF MOTION FOR 2 ROTATING MASSES COUPLED BY A SHAFT | |

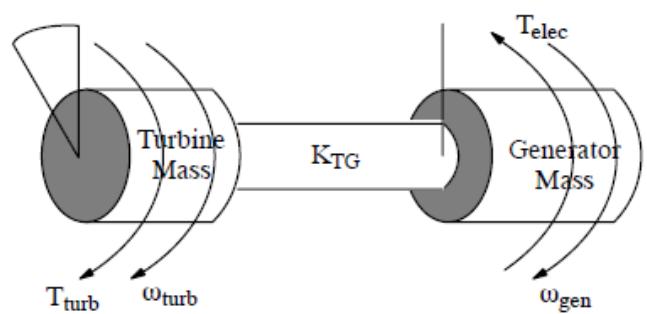

|  | |

| Figure 4.4: Two Rotating Masses | |

| The equations developed above are now extended to two masses coupled by a shaft. One mass represents a turbine and the other the rotating mass of the generator. The mass of the shaft itself is lumped proportionally into the rotating mass' inertia constants. The shaft connecting the generator mass to the turbine mass is considered as a torsional spring. Torque transferred across the shaft between the turbine and the generator results in | |

| twisting of the shaft. The amount of twist depends on the torque transferred across the shaft and on the torsional strength of the material comprising the shaft. | |

| $$ | |

| T = K\theta_{m} \tag{12} | |

| $$ | |

| T Torque transferred across the shaft $(N_{1}m)$ $\theta_{m}$ Mechanical angle of twist across the shaft (rad) K Shaft Stiffness $(N_{1}m / rad)$ | |

| The shaft stiffness constant $(K)$ defines the torque required to create an angular twist of 1 radian across the shaft. Values of K are typically very large since the torque, in N/m, required to twist a large turbo generator shaft by 1 radian (\~57 degrees) is significant. In order to use [12] with [11] developed above, equation [12] needs to be converted so as to relate per- unit torque to per- unit angle. Using the base values for mechanical angle and torque as shown below - | |

| $$ | |

| \begin{array}{r}\theta_{m_{base}} = \omega_{0m}\\ T_{base} = \frac{VA_{base}}{\omega_{0m}} \end{array} | |

| $$ | |

| the base shaft stiffness may be computed as - | |

| $$ | |

| K_{base} = \frac{VA_{base}}{\omega_{0m}} | |

| $$ | |

| $\omega_{0m}$ rated rotational speed of the mass in mech. rad/sec. | |

| The torque applied by the shaft to the masses to which it is attached is given by - | |

| $$ | |

| \begin{array}{l}{T_{T G} = K_{T G}(\theta_{T} - \theta_{G})}\\ {}\\ {T\qquad \mathrm{in~pu~if~}K_{T G}\theta \mathrm{~in~pu~}} \end{array} | |

| $$ | |

| The equations of motion for the two rotating masses can now be written - | |

| Generator Mass | |

| Turbine Mass | |

| Shaft Angle | |

| $$ | |

| \begin{array}{c}{2H\frac{dw_{gen}}{dt} = T_{turb} - T_e - D_{gen}\omega_{gen}}\\ {2H\frac{dw_{gen}}{dt} = T_{turb} - D_{turb}\omega_{turb}}\\ {\theta_T - \theta_G = \frac{T_{turb} - T_e}{K_{TG}}} \end{array} \tag{13} | |

| $$ | |

| All quantities in per- unit | |

| Equations [13] and [14] can be solved numerically using the trapezoidal rule as - | |

| $$ | |

| 2H\frac{\omega(t) - \omega(t - \Delta t)}{\Delta_t} +D\frac{\omega(t) - \omega(t - \Delta t)}{2} +K\frac{\theta(t) + \theta(t - \Delta t)}{2} = \frac{T(t) + T(t - \Delta t)}{2} \tag{16} | |

| $$ | |

| All of the history terms (ie. those at $t - \Delta t$ ) are known at the start of a new time- step. $2H$ , $D$ , $K$ and $\Delta t$ are constants and the new value of applied torque $T(t)$ is assumed to be known. The values $\omega (t)$ and $\theta (t)$ are unknown at the beginning of the time- step. Using the relation (17a) and applying trapezoidal rule an expression for $\theta (t)$ can be derived in terms of $\omega (t)$ . | |

| $$ | |

| \begin{array}{c}\frac{d\theta}{dt} = \omega \\ \displaystyle \frac{\theta(t) - \theta(t - \Delta t)}{dt} = \frac{\omega(t) + \omega(t - \Delta t)}{2}\\ \displaystyle \theta (t) = \frac{\Delta t}{2} [\omega (t) + \omega (t - \Delta t] + \theta (t - \Delta t) \end{array} \tag{17b} | |

| $$ | |

| Equation [17c] can be substituted into [16] to eliminate the $\theta (t)$ term and leave $\omega (t)$ as the only unknown. | |

| $$ | |

| \omega (t)\left[\frac{2}{\Delta t} 2H + D + \frac{\Delta t}{2} K\right] = | |

| $$ | |

| $$ | |

| T(t) + T(t - \Delta t) + \omega (t - \Delta t)\left[\frac{2}{\Delta t} 2H - D - \frac{\Delta t}{2} K\right] - 2K\theta (t - \Delta t) \tag{18} | |

| $$ | |

| $$ | |

| \begin{array}{c}{d e f i n e A = \left[\frac{2}{\Delta_{t}} 2H + D + \frac{\Delta_{t}}{2} K\right]}\\ {B = \left[\frac{2}{\Delta_{t}} 2H - D - \frac{\Delta_{t}}{2} K\right]} \end{array} \tag{19} | |

| $$ | |

| solving for $\omega (t)$ in [18] substituting $A$ and $B$ as defined above yields - | |

| $$ | |

| \omega (t) = A^{-1}[T(t) + T(t - \Delta t) + \omega (t - \Delta t)[B] - 2K\theta (t - \Delta t)] \tag{20} | |

| $$ | |

| Equation [20] is solved for each mass substituting in the appropriate parameters for $H$ , $D$ and $T$ . | |

| It is worth noting that the constants defined in [19] include terms which are multiplied by $2 / \Delta t$ and $\Delta t / 2$ . For a typical simulation time- step of $50 \mu s$ these multiplying factors vary by ten orders of magnitude. Given typical values for $H$ and $K$ the constants can be computed as - | |

| $$ | |

| \begin{array}{l}\frac{2}{\Delta t} *2H = \frac{2.0}{50e^{-6}} *2*0.8688 = 69,504.0\\ \displaystyle \frac{\Delta t}{2} *K = \frac{50e^{-6}}{2.0} *14042.92 = 0.3511 \end{array} | |

| $$ | |

| Even with the typically large difference in magnitude between $H$ and $K$ the elements comprising constants $A$ and $B$ are still different by five orders of magnitude. As for the damping factor $(D)$ which is also required to compute $A$ and $B$ , there is little in the way of typical data available in the literature. In many cases the damping is set to zero. | |

| # 4.5 MULTI-MASS MODEL USING MATRIX FORMULATION | |

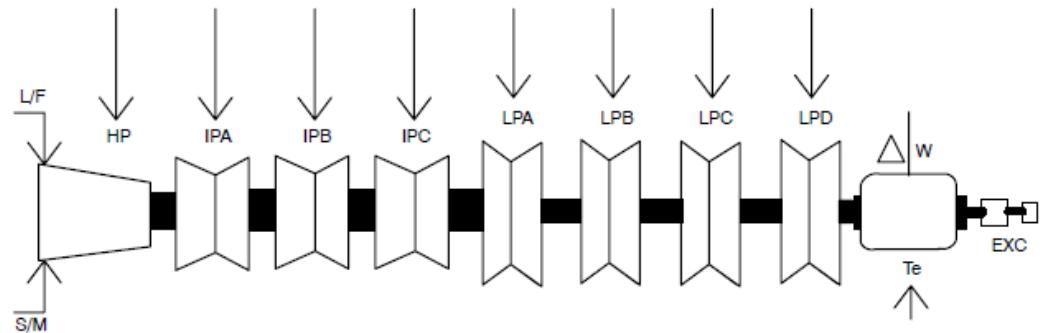

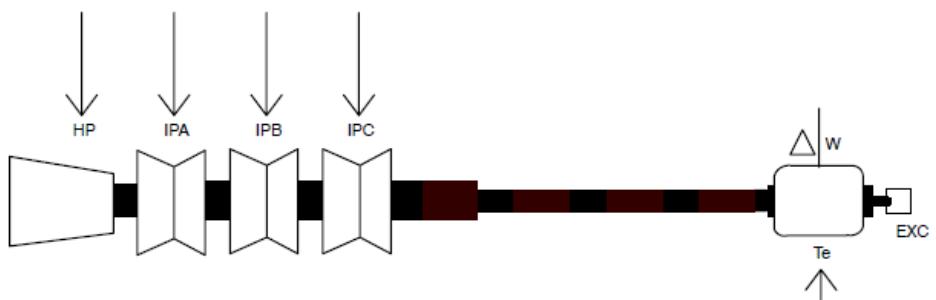

| Representation of n masses coupled by shaft segments is straight forward. By arranging the equations developed for 2 masses in matrix form, the solution can be generalized to any number of masses. For the present model, matrix sizes are dimensioned to permit eight turbine masses, one generator mass and two rotating exciter masses for a total of 11 coupled masses. | |

|  | |

| Figure 4.5: Multi Mass | |

| Equation [20] re- written in matrix form is - | |

| $$ | |

| [\omega_{n}(t)] = [A^{-1}][[T_{n}(t - \Delta t)] + [\omega_{n}(t - \Delta t)][B] - [2K][\theta_{n}(t - \Delta t)] \tag{21} | |

| $$ | |

| where - | |

| $n$ mass index 1. .. number of masses $[\omega_{n}(t)]$ newly computed speed of mass n $[A^{- 1}]$ inverse of tri- diagonal matrix A (full matrix) $T_{n}(t)$ latest value of torque applied to mass n | |

| $T_{n}(t - \Delta t)$ previous value of torque applied to mass n $[\omega_{n}(t)]$ previously computed value of speed of mass n [B] tri- diagonal matrix of B constants [2K] tri- diagonal matrix of $2*K$ spring constants $[\theta_{n}(t - \Delta t)]$ previous value of mass angle [D]: tri- diagonal damping coefficient matrix used in the calculation of the $A$ and $B$ matrices. | |

| The damping matrix includes both terms for the diagonal and off diagonal elements. Diagonal elements represent the self- damping factors (friction, windage) described above. Off- diagonal terms represent the damping due to the twisting of the shaft. Under transient conditions, when a varying torque is applied across the shaft segments, the back and forth twisting of the shaft results in heating and hence some damping. Data for this mutual damping is often not available. Note that the mutual damping is across a shaft segment so that only the $n - 1$ , $n$ and $n + 1$ elements of the damping matrix have non- zero terms. | |

| $$ | |

| D = \left[ \begin{array}{cccc}X_{11} & X_{12} & 0 & 0\\ X_{21} & X_{22} & X_{23} & 0\\ 0 & X_{32} & X_{33} & X_{34}\\ 0 & 0 & X_{43} & X_{44} \end{array} \right] \tag{22} | |

| $$ | |

| Damping Matrix form for 4 mass system | |

| # 4.6 MULTI-MASSMODELALGORITHM | |

| The algorithm for the multi- mass model is based on the solution of equation [21] above. The dimension of matrices and column vectors required for the solution is determined by the number of masses that constitute the system under study. Solution of [21] requires that mechanical torque applied to the turbines, electrical torque from the generator, a number of constants and information from the previous time- step are known. | |

| Mechanical torque to each turbine is provided as input to the multimass model from a separate component which models the speed control and torque production. Electrical torque is provided as output from the synchronous machine model or from the induction motor model and passed to the multimass model. User entered data, $H_{n},K_{n},D_{n}$ and simulation time- step are used to compute constants $A1,B$ and $[2K]$ | |

| Solution of [21] solves for mass rotational speeds from which mass angles and shaft torques can be computed. These quantities are provided as output from the multimass model. | |

| A mechanism is provided to lock all of the modelled mass speeds to a specified speed (often synchronous speed). A lock/free switch can be created in RSCAD/RunTime as part of the model, or the user can provide the lock/free signal input from an external signal. When in lock mode, all mass rotational speeds are set equal to the specified speed. Lock mode is often used to temporarily bypass the turbine dynamics during initialization of the power system to which the multimass system is connected. | |

| It is also possible operate the multimass model so as to lump all of the masses into a single rotating mass. In this way the shaft dynamics can be removed. A single/multi switch can be created in RSCAD/RunTime as part of the model, or the user can specify that the single/multi signal come from an external source. When in single mode, the torques applied to all of the turbine masses are added to form a single mechanical torque input. The equivalent mass' inertia constant is equal to the sum of all modelled masses. The sum of all the self damping terms is used for the damping. | |

| # 4.7 MODEL DEVELOPMENT USING C-BUILDER | |

| Development of the multi- mass model requires the following steps - | |

| # 4.7.1CONCEPTUAL LAYOUT OF THE NEW COMPONENT | |

| a. Which inputs should be connected using wires | |

| b. Which outputs should be connected using wires | |

| c. appearance of the component icon | |

| d. options which change appearance of icon | |

| e. What data is required to prepare the constants | |

| f. How to group related data fields | |

| g. What monitoring options should be available | |

| h. control system or power system component type | |

| # 4.7.2 COMPONENT ICON CREATION IN C-BUILDER (GRAPHICS & NODES) | |

| a. Define component as a Control system typecomponent | |

| b. locate and place all of the input / output points and add associated logic blocks | |

| c. Draw component icon portions which do not require conditional logic. | |

| d. Draw component icon portions for each option which changes the component's appearance. | |

| # 4.7.3 DEFINE USER SUPPLIED DATA MENUS (PARAMETERS) | |

| a. Add all of the data sections defined under I(f) above. | |

| b. Add logic to parameters so the parameter entry fields are visible only when the corresponding options are selected. | |

| # 4.7.4 WRITE DATA PREPARATION PORTION OF THE 'C' PROGRAM | |

| a. Create C File and Declare required variables | |

| b. Compute constants required for the executable code | |

| c. Optionally write critical data to the .map file | |

| # 4.7.5 WRITE 'C' CODE TO IMPLEMENT THE ALGORITHM | |

| a. Declare required variables | |

| b. Create variables for named output signals | |

| c. Create variables for named input signals | |

| # 4.7.6 TEST NEWLY DEVELOPED MODEL | |

| a. Check data preparation to ensure constants are computed correctly. | |

| b. Run simulation cases to confirm basic operation | |

| c. Run simulation cases to verify against benchmark cases | |

| # 4.7.7 CONCEPTUAL LAYOUT OF THE NEW COMPONENT | |

| a. Torque inputs to each turbine section and the generator $(Te)$ will be connected to input points. The user will thus be able to interconnect the governor/torque production model to the multimass model via wires. The synchronous generator model's Te output signal can also be connected to the multimass model via a wire component. | |

| b. The synchronous generator model requires the generator mass speed signal as an input. Note that the speed signal may change very little from simulation time-step to time-step. Within the GPC processor, computations are done using double (64 bit) precision. However, when the data is sent from the multimass model to the generator model over the rack backplane, the speed signal is converted to a single precision number. Rather than sending the speed signal directly from the multimass to the machine model, a delta-omega (ie. change from synchronous speed) signal is sent instead. | |

| Input and output points for the multimass model are shown in Figure 4.6. | |

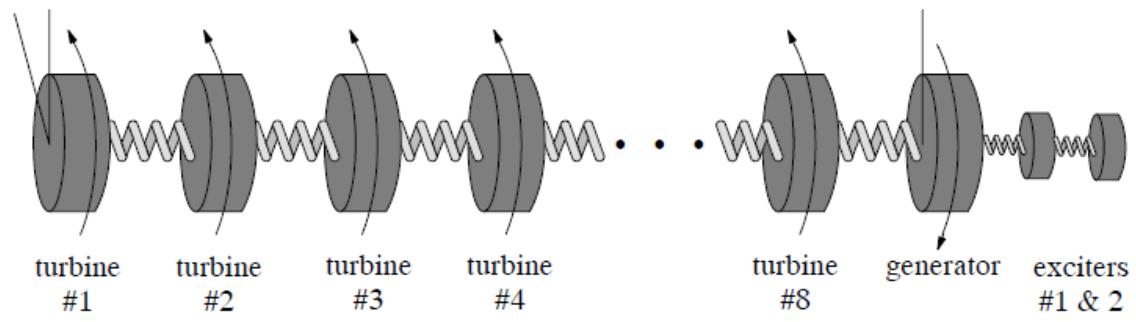

|  | |

| Figure 4.6: Input and Output Points | |

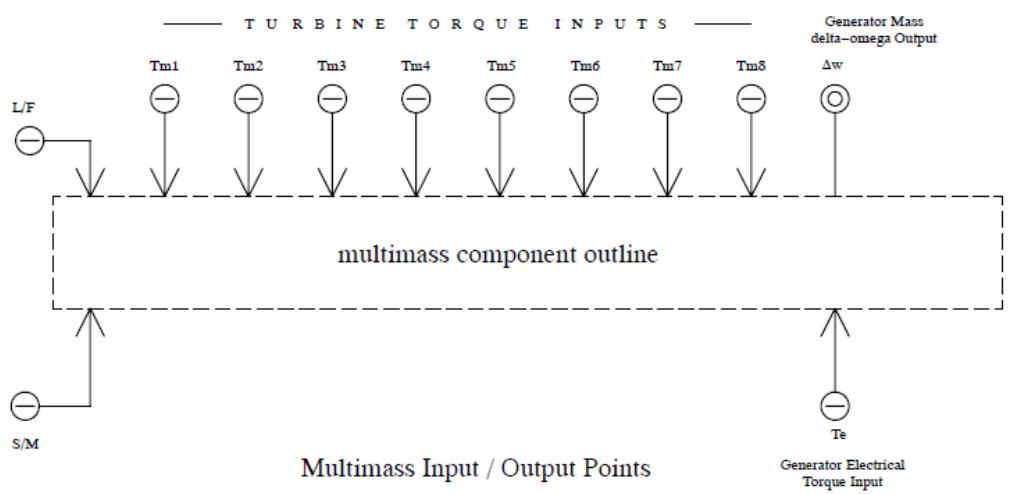

| c. The component's appearance is shown in Figure 4.7. Each of the turbine torque inputs connects to an icon representing a single turbine mass. Electrical torque is connected as an input to an icon representing the rotating portion of the generator. A change from synchronous speed signal for the generator mass is available as an output. At synchronous speed this signal is equal to 0.0. Two exciter masses are connected on the right side of the generator mass. | |

|  | |

| Figure 4.7: Multimass Component Appearance | |

| d. There are a number of options which may be set by the user which require the appearance of the component icon to change - | |

| Number of turbine masses (1- 8) Number of exciter masses (0- 2) Lock/Free switch input mode Single/Multi switch input mode | |

| The generator mass and HP turbine mass are always drawn. If the number of turbines is set less than 8, then unused turbine icons are replaced by extending the shaft between the generator and last turbine. Exciter masses are drawn only if selected. | |

|  | |

| Figure 4.8: Extended Shaft Between the Generator and Turbine | |

| Multi- Mass component icon with 4 turbine masses, 1 exciter mass and switch inputs created as part of the model. | |

| e. The following data must be supplied by the user before the constants required for the algorithm can be computed - | |

| $H$ Inertia Constant for each mass (MW sec / MVA) $K$ Spring Constant for each shaft (in pu) $D_{s}$ Self Damping for each mass (in pu) $D_{m}$ Mutual Damping for each shaft section (in pu) | |

| Logic is included as part of the component so that only the data required for the number of selected turbines needs to be entered. Data items not required for the selected configuration appear grey in the menus and cannot be selected for input. | |

| f. The following data tabs are defined for the multi-mass component - | |

| CONFIGURATION Basic configuration options INERTIA CONSTANTS $H$ values for each mass SHAFT SPRING CONSTANTS $K$ values for each shaft section SELF DAMPING $D_{s}$ values for each mass MUTUAL DAMPING $D_{m}$ values for each shaft section MONITORING OPTION TABS see below | |

| g. The user is able to select the following items for monitoring. | |

| These are named variables and as such there is no wire protruding from the component icon for any of these outputs. | |

| Mass Speed Mass Angle with respect to the generator Shaft Torque | |

| Tabs are included in the component icon to facilitate selection of the signals to be monitored and the name assigned to each monitored variable. Logic is included as part of the component to permit selection of only those variables which are computed for the specified configuration. | |

| h. C-Builder requires that the user specify whether the component is a power system or control system type component. Power system components connect to power system nodes as defined by node icons in RSCAD/Draft and often contribute current injections into those nodes to which the component is connected. Control system components do not connect to power system nodes and are not able to supply current injections into the power system network. | |

| The GPC processor to which a control system component is allocated automatically becomes a control system processor for the simulation case and only other control system components maybe allocated to that processor. It is not possible to allocate both control system and power system components to the same GPC processor. | |

| # 4.7.8 COMPONENT ICON CREATION IN C-BUILDER | |

| The C- Builder Users Manual should be consulted for additional details on defining the component icon. Information provided here outlines the major steps required to complete the icon associated with the multi- mass model. | |

| a. Define the Component as a Control System Component | |

| When a new component is created the user is prompted to select whether the component type is control or power system. For the multimass model select control. | |

| The component type can be changed after a new component is created from the "Other" tab. | |

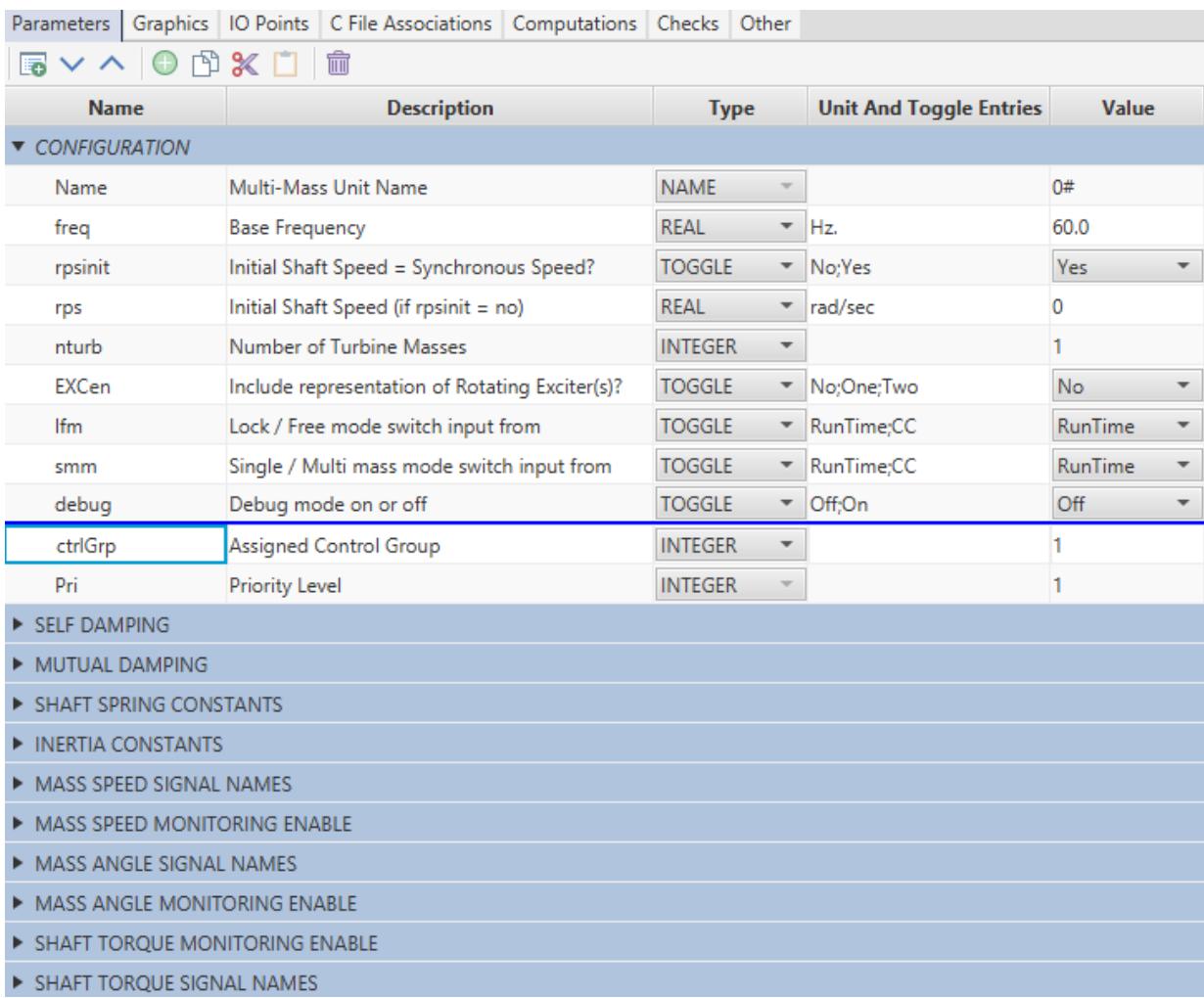

| b. Define the Input/Output points and associated conditional logic under the IO Points Tab | |

| Torque input for the HP Turbine, electrical Torque input to the generator and generator delta- omega output are always present. No logic needs to be placed around these input / output points. Select the create input/output point button from the drawing toolbar and left click when the circle is positioned as shown in Figure 4.9. Use the create input/output function to create points for the HPT input, The input and delta- omega output signals. A menu for the input/output point name and type (input or output, int or real) appears at the bottom when a input/output point is selected. All of the torque inputs are specified as real type. | |

|  | |

| Figure 4.9: IO Points | |

| The number of turbines included in each instance of the component is set by the user. Torque inputs for turbines other than for the HP turbine need to be placed inside conditional logic so that the inputs are enabled only when dictated by the number of selected turbines. To define a new condition, under the IO Points section, left click the add condition button and select the if option from the pull down. Enter the logic condition as shown below. The parameter nturnb, defined later, holds the number of turbines selected by the user. | |

|  | |

| Figure 4.10: Input/Output Points Details | |

| While the If (nturb>1) - EndIf block is highlighted in the IO Points section, add the input point for the IPA torque signal. The new input point is created inside the highlighted If- EndIf logic. | |

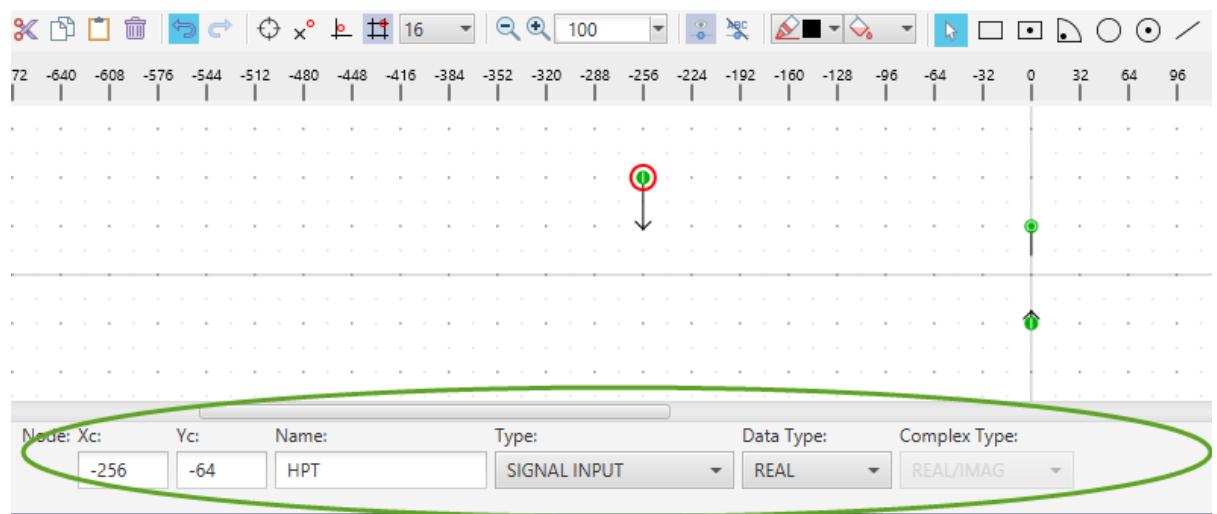

| Data under the IO Points tab should appear as shown in Figure 4.11 once all of the input / output points and associated logic has been entered. | |

|  | |

| Figure 4.11:Data Under the I/O Points Tab | |

| c. Draw the unconditional graphics. | |

| d. Draw the conditional graphics. | |

| Turbine blocks which are not enabled are replaced by a shaft section for the component's appearance in RSCAD/Draft. Exciter masses are only drawn if enabled. L/F (Lock/Free) and S/M (Single/Multi) input wires are only drawn if the user selects these inputs are to come from a signal input rather than an RSCAD/RunTime switch. | |

| To add a logic condition under the Graphics tab select the Add Condition button and choose the if option from the pulldown. Enter the condition appropriate for the turbine section which is to be drawn within the logic condition. Since either a shaft section or turbine icon will be drawn, an if- else- endifstructure is required. To add an else section, highlight the newly created if- EndIf condition by left clicking on the If statement (the If and EndIf lines will turn red). Left click the Add Condition button and this time select Else from the pull down that appears. | |

| The condition logic should appear as follows - | |

| if (nturb>1) Else EndIf | |

| To add drawing commands into a particular condition, left click the small arrow next to the logic condition in which the drawing commands are to be placed. The condition turns red and the arrow should point downwards. Use the drawing commands to draw the shapes required for the icon portion. Drawing commands are placed within the highlighted logic condition. To draw the icon portion in the else section left click the small arrow next to the if line so that it again points to the right. The components drawn within the if section disappear from the drawing canvas. Now left click the small arrow next to the else line. The line becomes red and the arrow points downward. Draw the shapes required for the else portion of the icon. Repeat the above procedure for each turbine section. | |

| The multimass model permits representation of up to 2 rotating exciters. No torque input is applied to these exciter masses. A variable named "EXCen" is set to 0/1/2 by the user to indicate the number of exciter masses to be modelled. The logic for drawing the exciters can be arranged as follows - | |

| If (EXCen > 0) Draw shapes to represent exciter net to generator EndIf | |

| If (EXCen == 2) Draw shapes to represent 2nd exciter EndIf | |

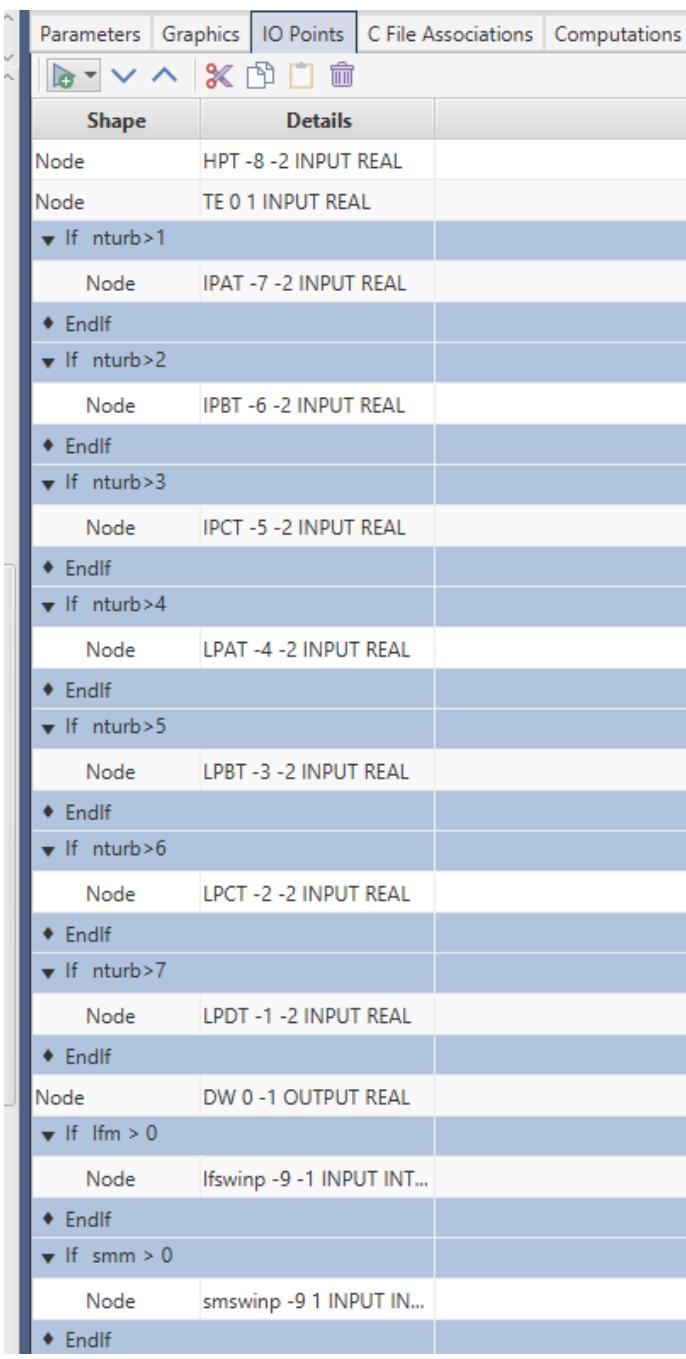

| # 4.7.9 ADD PARAMETER ENTRY MENUS | |

| a. Now that the component icon, including input / output points and conditional graphics have been completed the menus for data entry are created. These menus are defined under the Parameters tab in the control pane area of the RSCAD/C-Builder window. | |

| The following sections are required for the multimass component. | |

| CONFIGURATION: basic configuration parameters including the number of turbines to be represented (nturb) and how many exciter masses are to be modelled (EXCen) SELF DAMPING: the self damping factors for each modelled mass. MUTUAL DAMPING: the damping factors for the shafts connecting the modelled masses. SHAFT SPRING CONSTANTS: the spring constants for the shafts connecting the modelled masses. INERTIA CONSTANTS: the inertia constants for each modelled mass. MASS SPEED MONITORING ENABLE: enable speed monitoring for each modelled mass. MASS SPEED SIGNAL NAMES: signal name for each monitored mass speed signal. MASS ANGLE MONITORING ENABLE: enable monitoring for the angle between each modelled mass. MASS ANGLE SIGNAL NAMES: signal name for each monitored mass angle signal. SHAFT TORQUE MONITORING ENABLE: enable shaft torque monitoring for each modelled shaft segment. SHAFT TORQUE SIGNAL NAMES: signal name for each monitored shaft torque signal. | |

| To create the component data entry sections listed above, left click the add section button in the control pane area of the RSCAD/C- Builder window. Enter the Section name in the menu that appears. | |

| None of the sections need an associated logic condition. | |

| Once all of the data entry sections have been created, left click the small arrow next to the section to which the parameters are to be added. The arrow points down and the section heading is highlighted. Left click the add parameter button and fill in the appropriate data in the menu that appears. The new parameter entry element is added under the highlighted section. | |

|  | |

| Figure 4.12: Parameters Tab | |

| b. Some parameters should only permit data entry when required. | |

| For example, if the user specifies that only 1 turbine mass is to be modelled (nturb = 1) then data for the IPA, IPB ... LPA turbine masses is not necessary and the associated parameters should not permit data entry. To facilitate this, a logic condition may be added to each parameter. | |

| To enable data entry for the IPA inertia constant only when the IPA turbine is to be modelled, add the following logic condition to the IPAH parameter entry - | |

| nturb>1 | |

| If the nturb parameter defined under the CONFIGURATION menu is set to 1 by the user then the IPAH parameter entry line will be greyed out. | |

| Names for monitored signals should only be entered if the associated turbine is modelled AND if the user has enabled that signal for monitoring. In this case the AND function can be used in the logic condition - | |

| nturb>1 &&HPIPATen | |

| # 4.7.10 WRITE DATA PREPARATION PORTION OF THE 'C' PROGRAM | |

| a. Create C File and Declare Variables | |

| There are two 'C' code programs that must be written by the user to complete the model. Firstly, a 'C' program which computes the constants required by the algorithm must be written. Secondly, the program which executes the algorithm for the model must be written. Only the second program runs on the RTDS hardware. Both 'C' programs are stored in the same file. A template for the 'C' file is created by selecting the "Add Model" button under the C File Associations tab. The newly created file can be edited by selecting the edit button. | |

| All of the input / output signals and parameters, as well as, their types are listed in a .h file which is automatically generated by C- Builder. The .h file is included as part of the 'C' code using the #include statement at the top of the 'C' code file. As such, all of the input / output and parameter signals may be used as part of the 'C' code. The simulation time- step may be obtained by adding the following statement into the 'C' code - | |

| The algorithm to be solved for the multimass model is essentially defined in equation 21 above. In order to solve [21] the following matrices must be computed as part of the data preparation code. | |

| <table><tr><td>[H], [D], [K]</td><td></td></tr><tr><td>[A], [B]</td><td></td></tr><tr><td>[A] -1</td><td></td></tr></table> | |

| The matrices are declared as double precision and dimensioned to the maximum number of masses (= 8 turbine masses + 1 generator mass + 2 exciter masses = 11 masses). | |

| RAM: #define MAXMASS 11 double H[MAXMASS][MASSMASS]; double K[MAXMASS][MASSMASS]; double D[MAXMASS][MASSMASS]; double A[MAXMASS][MASSMASS]; | |

| double B[MAXMASS][MASSMASS]; | |

| The above matrices are declared under the RAM: section in the 'C' code file since they are only used for the data preparation. The matrix Ainverse is required in both the data preparation and algorithm portions of the 'C' code and as such is declared under the STATIC: section of the 'C' code file. | |

| STATIC: double AINV[MAXMASS][MAXMASS]; | |

| # b. Load Data into Variables | |

| Data storage into the matrices and arrays is such that the lowest indexed entry is allocated to the High Pressure turbine. The next entry to the IP turbine and so on. Generator data is entered into the element pointed to by nturb. Exciter #1 is entered into the element pointed to by nturb+1. For example if the user has specified that four turbine masses are to be modelled (nturb=4) then the following code would be used to load the H matrix elements. Note that the inertia constants are loaded into the diagonal elements only and that off- diagonal elements of the H matrix are 0.0. | |

| $\begin{array}{rl}\mathbb{H}[0][0] & = \mathbb{HPH};\\ \mathbb{H}[1][1] & = \mathbb{IPAH}; \end{array}$ $\begin{array}{rl}\mathbb{H}[7][7] & = \mathbb{LPAH}; \end{array}$ H[ntrub][ntrub] $=$ GENH; H[ntrub+1][ntrub+1] $=$ EXC1H; H[ntrub+2][ntrub+2] $=$ EXC2H; | |

| The $D$ and $K$ matrices are tri- diagonal (see equation [22]) meaning that only their diagonal and diagonal $+ / - 1$ elements have non- zero values. Elements of these matrices are loaded one value at a time - | |

| D[0][0] $=$ HPSD $^+$ HPIPAMD; D[0][1] $=$ - HPIPAMD; D[1][0] $=$ - HPIPAMD; D[1][1] $=$ HPIPAMD $^+$ IPASD $^+$ IPAIPBMD; D[1][2] $=$ - IPAIPBMD; | |

| D[7][7] $=$ LPCLPDMD $^+$ LPDSD $^+$ LPGENMD; D[nturb][nturb] $=$ GENSD $^+$ LPGENMD; | |

| Exciter damping factors are added into nturb $^{+1}$ and nturb $^{+2}$ elements. | |

| Elements of the $K$ matrix are filled in using the same procedure as for the $D$ matrix. Once the $K,D$ and $H$ matrix elements are filled, the $A$ and $B$ matrices are computed as follows (see equation [19]). Computations are done only for the number of masses which are being modelled. | |

| nmass $=$ nturb $^{+1 + }$ EXCen; $\mathtt{K1} = \mathtt{4} / \mathtt{dt}$ $\mathtt{K2} = \mathtt{dt} / 2$ for (row $= 0$ ;row<nmass,row++) { for (col $= 0$ ;col<nmass;col++) { A[row][col] $= \mathbb{H}$ [row][col]\*k1+D[row][col] $^+$ K[row][col]\*k2; B[row][col] $= \mathbb{H}$ [row][col]\*k1- D[row][col] $^+$ K[row][col]\*k2; } } | |

| The inverse of the A matrix is required for the algorithm (see equation [21]). An internal matrix inversion routine is available to generate the required inverse matrix - | |

| $\dot{\texttt{i}} =$ matx invert(nmass,A,MAXMASS,AINV,MAXMASS); where - nmass $=$ dimension of matrix to invert $\mathtt{A} =$ matrix to invert MAXMASS $=$ dimension of matrices A and AINV $\mathtt{AINV} =$ matrix to store inverse of A | |

| The Ainv matrix is a full matrix. In addition to the Ainv matrix, the algorithm portion of the $^{\prime}C^{\prime}$ code also requires the B matrix and 2 times the k matrix. However, the B and $2^{n}k$ matrices are tri- diagonal and to conserve computations they will be stored in eleven separate arrays of dimension three. Each array holds the $n - 1$ n and $n + 1$ elements (where n is the diagonal element). Since these vectors are used in both the data preparation and algorithm portion of the $^{\prime}C^{\prime}$ code they are declared under the STATIC: section - | |

| STATIC: double K2TRIO[3], BTRIO[3]; double K2TRI1[3], BTRI1[3]; double K2TRI10[3], BTRI10[3]; | |

| The K2TRI and BTRI vectors are loaded from the K and B vectors. | |

| for $(\dot{1} = 0;\dot{1} < 3;\dot{1} + + )$ { BRTRIO[i] $=$ B[0][i]; K2TRI0= 2.0 \* K[0][i]; BTRI10[i] $=$ B[10][i+8]; K2TRI10[i] $=$ 2.0 \* K[10][i+8]; } | |

| c.Write Critical Data to the .map File | |

| It may be useful to include an option in the component's CONFIGURATION menu to print computed data into the .map file. Such data may be useful for debugging purposes during the model's development and testing, as well as, solving problems that may arise if third parties begin to use the model. | |

| Printing to the .map file may be done using the following structure of the fprintf statement | |

| fprintf(mapFile,"\n D[%d][%d] = %lf", row, col, D[row][col]); | |

| # 4.7.11 WRITE 'C' CODE TO IMPLEMENT THE ALGORITHM | |

| Now that all of the constants required for the algorithm have been computed, the 'C' code to implement the algorithm itself can be written. Code to execute the model algorithm is placed under the CODE: section in the 'C' file template. The basic structure of the code is as follows - | |

| variable declarations initializing If (mode $= =$ lock) { set all mass speeds } Else if (mode $=$ single) { solve one mass model } Else | |

| { compute multimass algorithm } write output signals | |

| The algorithm used to solve the multimass model is based on equation [21] (repeated below) and proceeds in the following steps. | |

| $$ | |

| [\omega_{n}(\tau)] = [A^{-1}]*[[T_{n}(\tau)] + [T_{n}(\tau -\Delta \tau)] + [B][\omega_{n}(\tau -\Delta \tau)] - [2K][\theta_{n}(\tau -\Delta \tau)] | |

| $$ | |

| 1. Compute $[BW] = [B]*[\omega (t - dt)]$ . Since only the non-zero elements of $[B]$ are stored the calculation is done as follows - | |

| $$ | |

| \left[ \begin{array}{c}BW_0\\ BW_1\\ BW_2\\ BW_3 \end{array} \right] = \left[ \begin{array}{cccc}B_{00} & B_{01} & 0 & 0\\ B_{10} & B_{11} & B_{12} & 0\\ 0 & B_{21} & B_{22} & B_{23}\\ 0 & 0 & B_{32} & B_{33} \end{array} \right]\left[ \begin{array}{c}Wold_0\\ Wold_1\\ Wold_2\\ Wold_3 \end{array} \right] | |

| $$ | |

| BW[0] $=$ BTRIO[0] \* wold[0] $^+$ BTRIO[1] \* wold[1]; BW[1] $=$ BTRI1[0] \* wold[0] $^+$ BTRI1[1] \* wold[1] $^+$ BTRI1[2] \* wold[2]; BW[2] $=$ BTRI2[0] \* wold[1] $^+$ BTRI2[1] \* wold[2] $^+$ BTRI2[2] \* wold[3]; BW[3] $=$ BTRI3[0] \* wold[2] $^+$ BTRI3[1] \* wold[3] $^+$ BTRI3[2] \* wold[4]; | |

| 2. Compute $[K2TH] = [K2]*[THold(t - dt)]$ . Since only the non-zeroelements of [K2] are stored the calculation is done as follows - | |

| $$ | |

| \left[ \begin{array}{c}K2TH_0\\ K2TH_1\\ K2TH_2\\ K2TH_3 \end{array} \right] = \left[ \begin{array}{cccc}K2_{00} & K2_{01} & 0 & 0\\ K2_{10} & K2_{11} & K2_{12} & 0\\ 0 & K_{21} & K2_{22} & K2_{23}\\ 0 & 0 & K2_{32} & K2_{33} \end{array} \right]\left[ \begin{array}{c}THold_0\\ THold_1\\ THold_2\\ THold_3 \end{array} \right] | |

| $$ | |

| K2TH[0] $=$ K2TRIO[0] \* THold[0] $^+$ K2TRIO[1] \* THold[1]; K2TH[1] $=$ K2TRI1[0] \* THold[0] $^+$ K2TRI1[1] \* THold[1] $^+$ K2TRI1[2] \* THold[2]; K2TH[2] $=$ K2TRI2[0] \* THold[1] $^+$ K2TRI2[1] \* THold[2] $^+$ K2TRI2[2] \* THold[3]; K2TH[3] $=$ K2TRI3[0] \* THold[2] $^+$ K2TRI3[1] \* THold[3] $^+$ K2TRI3[2] \* THold[4]; | |

| 3. Compute $[Bcol] = [Told] + [BW] - [K2TH]$ . $[BW]$ and $[K2TH]$ were computed in steps 1 and 2 above. $[Told]$ are the shaft torques computed in the previous time-step. $[Told]$ , $[BW]$ and $[K2TH]$ are column vectors and can thus $[Bcol]$ may be computed | |

| using a for loop as shown below - | |

| for (ii=0;ii<nmass;ii++) { $\mathtt{BCOL}[\mathtt{ii}] = \mathtt{T}[\mathtt{ii}] + \mathtt{BW}[\mathtt{ii}] - \mathtt{K2TH}[\mathtt{ii}];$ } | |

| 4. Compute $[\mathtt{Bcol}] = [\mathtt{Bcol}] + [\mathtt{T}]$ . The [T] vector is the latest shaft torques which must first be read in from the external source. Only those input torques associated with masses that are actually modelled may be read in. Once read, the new shaft torques can be added to the [BCOL] vector computed in step 3a. | |

| T[0] $=$ HPT; if (nturb $= = 8$ { T[1] $=$ IPAT; T[2] $=$ IPBT; T[3] $=$ IPCT; T[4] $=$ LPAT; T[5] $=$ LPBT; T[6] $=$ LPCT; T[7] $=$ LPDT; } else if (nturb $= = 7$ { } else if (nturb $= = 2$ { T[1] $=$ IPAT; } for (ii $= 0$ ;ii<nmass;ii++) { $\mathtt{BCOL}[\mathtt{ii}] = \mathtt{BCOL}[\mathtt{ii}] + \mathtt{T}[\mathtt{ii}];$ } | |

| 5. Compute [w] = [Ainv]*[BCOL]. Matrix [Ainv] is stored as a full nxn matrix and as such for loops can be used to compute the new mass speed vector [W]. | |

| for (ii=0;ii<nmass;ii++) { w[ii] $= 0,0$ for (jj=0;jj<nmass;jj++) { w[ii] $=$ w[ii] $^+$ Ainv[ii][jj]\*BCOL[jj]; } | |

| } | |

| 6. With the new speeds of each modelled mass known from step 4, it is now possible to compute the angles of each mass. The computed mass angles are used in step 2 during the next time-step in the computation of speed. The vector THold is used to store the newly computed values of mass angles. | |

| dt2= 0.5\*de1t; for (ii=0;ii<nmass;ii++) { THold[ii] $=$ THold[ii] $^+$ dt2\*(wold[ii] $^+$ w[ii]); } | |

| The generator mass angle is chosen as the reference (0 deg). The computed generator mass angle is subtracted from each modelled mass, including the generator mass itself. | |

| for (ii=0;ii<nturb;ii++) { THold[ii] $=$ THold[ii] - THold[nturb]; } THold[nturb+1] $=$ THold[nturb+1]- THold[nturb]; THold[nturb+2] $=$ THold[nturb+2]- THold[nturb]; THold[nturb] $=$ 0.0; | |

| 7. Now that the multimass algorithm has been solved, monitored variables can be prepared. All of the computations done within the algorithm are based on per-unit quantities. Monitored variables need to be converted to the desired units prior to being written out. The following conversions are done - | |

| [w] speed pu \* 2\*PI\*Base_Freq - > speed in rad/sec [THold] shaft angle in pu \*360 \* 2\*PI\*Base_Freq - > shaft angle in degrees | |

| Shaft torques are computed using the angle across the shaft. For example, to compute the torque across the shaft connecting the HP and IPA masses - | |

| HPIPAT $=$ HPIPAK \* (THold[0]- THold[1]) where HPIPAK is the spring constant for the shaft | |

| 8. Some additional code needs to be added to the algorithm to handle the lock/free switch. The Ifm parameter under the CONFIGURATION menu permits the user to select whether the lock/ free switch is automatically created by the model or whether an external signal | |

| connected to an input point controls the lock/free operating mode of the multimass model. To handle both input options a variable lfmode is created and assigned input from the external signal or from the automatically created RSCAD/RunTime switch depending upon the selection of the lfm parameter. If the lfm parameter is equal to 0 then an RSCAD/RunTime switch is automatically created, otherwise the lock/free signal is read from an input point. | |

| if (lfm > 0) { lfmode = lfswinp; } else { lfmode = lfsw; } | |

| Both the lfswinp and lfsw variables are defined in the .h file that is created when the component is compiled. | |

| When the lock/free signal is set to free (lfmode=0), the algorithm as defined in steps 1- 6 above is executed. When in lock mode (lfmode = 1) all modelled mass speeds are fixed. | |

| k3= 1.0; if (rpsinit == 0) k3 = rps/omo; if (lfmode == 1) { for (ii=0;ii<nmass;ii++) { w[ii] = k3; } } | |

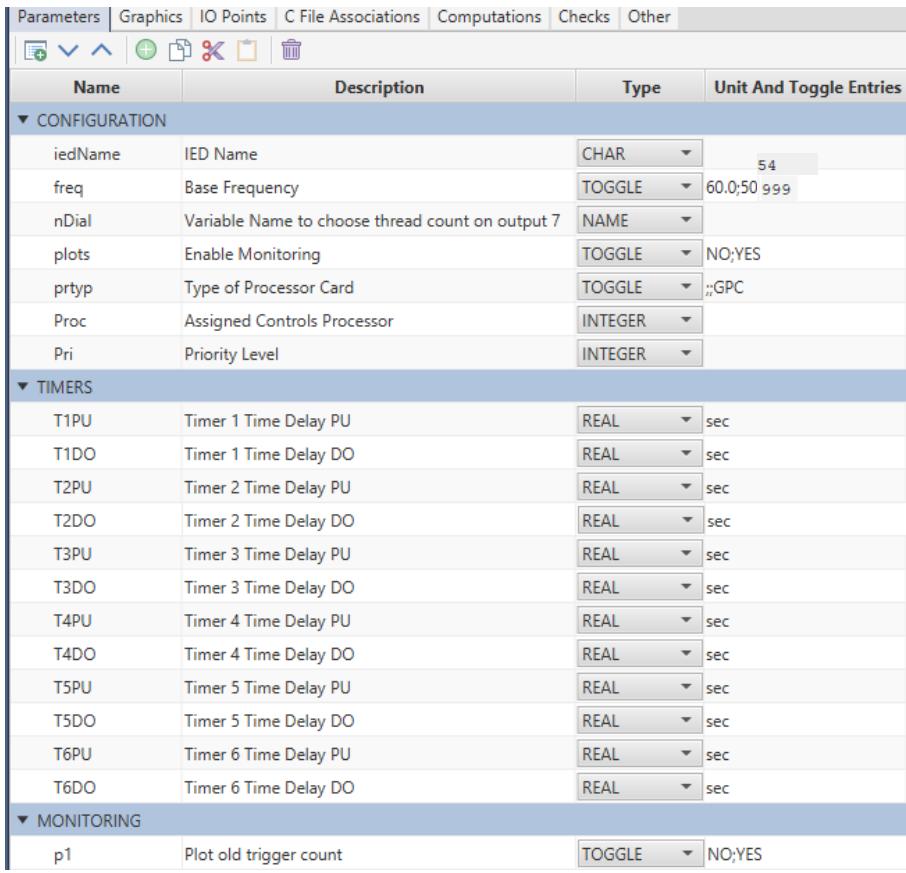

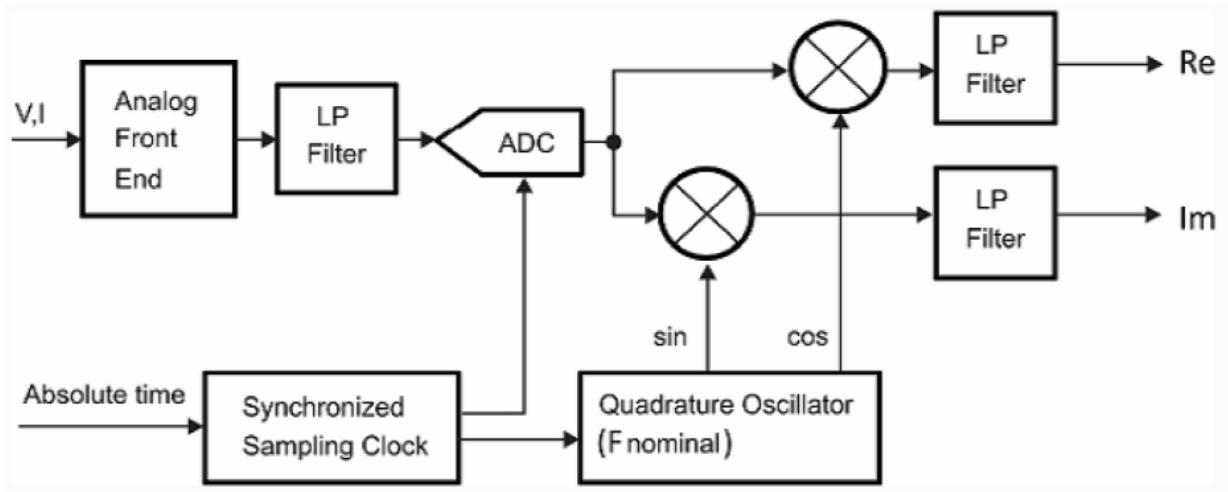

| The variable k3 is set to 1.0 (ie. 1.0 per- unit speed represents synchronous speed) if the rpsinit parameter is set to synchronous speed (rpsinit == 1 (Yes)) by the user. If the rpsinit parameter is set to non- synchronous speed (rpsinit == 0 (No)) then the specified initial speed is used to compute the initial per- unit speed of the machine and this value is used for all of the modelled mass speeds when operating in lock mode. | |